History of Industry Robot

The earliest known industrial robot that meets the ISO definition is the “Regulations” completed by Griffith P. Taylor in 1937 and published in Meccano Magazine, March 1938. It is almost exclusively a crane-like device built of Meccano pieces and powered by a single electric motor. Five axes of movement are possible, including grab-and-grab rotation. Automation is achieved by using perforated tape to energize the solenoid, which will facilitate the movement of the crane’s control rod. The robot can stack blocks in pre-set patterns. The number of motor revolutions needed for each desired motion is plotted on graph paper. This information is then transferred to a paper tape, which also drives the robot’s individual motors. In 1997, a complete copy of the robot built by Chris Schutte.

Georges DeVoe applied for a robotics in 1954 (awarded 1961). The first company to make robots was Unimation, founded by Devol and Joseph F. Engelberger in 1956, and was based on Devol’s original. Unimation robots are also known as programmable transfer machines, since at first their main use was to transfer objects from one point to another, less than ten feet or so apart. They used hydraulic actuators and programmed the joint coordinates, ie the angles of each joint during a teaching session for storage and playback operations. They are to 1/10,000th of an inch. After Unimation* its technology, Kawasaki Heavy Industries and GKN, manufacture Unimates in Japan and the UK respectively. For some time Unimation’s competitor was Milacron Corporation of Cincinnati, Ohio, USA. This changed fundamentally in the late 1970s when several large conglomerates in Japan began producing similar industrial robots.

Invented by Victor Scheinman at Stanford University in 1969, the Stanford Arm, an all-electric, 6-axis articulated robot design allows for a one-arm solution. This allows it to track arbitrary paths in space, broadening the potential use of the robot to more complex applications such as assembly and welding. Scheinman then designed the second arm of the MIT Artificial Intelligence Laboratory, dubbed “the MIT arm.” Scheinman, after receiving a scholarship from Unimation to develop his design, sold those designs to Unimation who further Developed with their backing, General Motors, which later marketed the Programmable Universal Machine Assembly (PUMA).

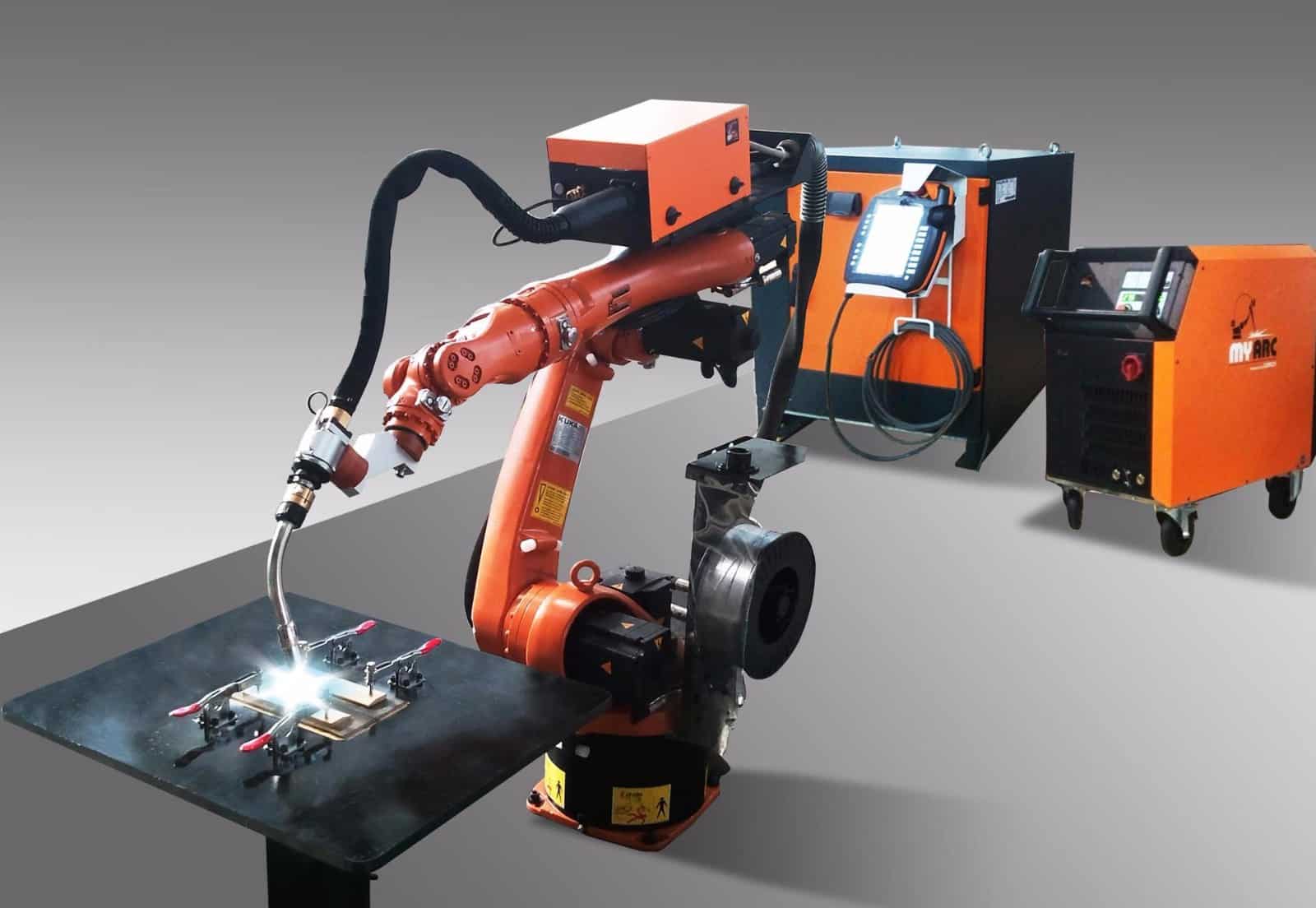

Industrial robots took off quite quickly in Europe, both ABB robots and KUKA robots brought to the robot market. In 1973, ABB robots (formerly ASEA) launched IRB 6, the world’s first commercially available all-electric microprocessor-controlled robot. The first two IRB 6 robots were sold to Magnussen in Sweden for grinding and polishing tube bending and were installed in production in January 1974. Also in 1973, KUKA Robotics built its first robot, called FAMULUS, also a 1-joint robot with 6 electromechanical drive axes.

Interest in robotics increased in the late 1970s, with many American companies entering the field, including large companies such as General Electric and General Motors (which formed a joint venture between FANUC Robotics and FANUC Japan Ltd). American startups include Automatix and Adept Technologies, Inc. At the height of the robotics boom in 1984, Unimation acquired Westinghouse Electric Company for $107 million. Westinghouse sold Unimation to Stäubli Fave de SCA of France in 1988, was also making articulated robots for general industrial and cleanroom applications, and even bought the Robotics Division of Bosch in late 2004.

Only a few non-Japanese companies manage to finally survive in this market, the main ones are: Adept Technology, Stäubli, Unimation, the Swedish-Swiss company ABB Asia Brown Boveri, the German company KUKA Robotics and Italian Company Comau.

Links: 3bsc950193r1 3bse008508r1

Pre: What is Vacuum Robot? Next: Huawei’s Ark compiler framework...