Transmission Lines of Industry Robot

System introduction

Robot and conveyor line logistics automation system mainly consists of the following parts:

Automatic conveying line: automatically convey the product, and position the tooling board of the product at each assembly station. After the assembly is completed, the tooling board can be automatically circulated; it is equipped with motor overload protection, and the drive chain is directly meshed with the conveyor chain, so that the transmission is stable , reliable operation.

Robot system: the assembly of components can be completed accurately and quickly by robots at specific stations, enabling the production line to achieve a high degree of automation; robots can be adjusted to each other in accordance with certain principles to meet the rhythm requirements of process points; The communication interface of the upper management system.

Automated three-dimensional warehousing and feeding system: Automatic planning and dispatching of assembly raw materials, timely delivery of raw materials to the assembly production line, and real-time statistics and monitoring of stock raw materials.

The main control system of the whole line: the control system based on the field bus—Profibus DP is adopted, which not only has excellent real-time performance, but also has excellent reliability.

Barcode data collection system: make various product manufacturing information standardized, accurate, real-time, and traceable. The system uses file servers and large-capacity storage devices to quickly collect and manage on-site production data.

Product automated testing system: test the performance indicators of the final product, and transfer unqualified products to the repair line.

Production line monitoring/scheduling/management system: The three-level network of management layer, monitoring layer and equipment layer is used to comprehensively monitor, dispatch, and manage the entire production line. It can accept workshop production plans, automatically assign tasks, and complete automated production.

Application field

Robot and conveyor line logistics automation system can be used in building materials, home appliances, electronics, chemical fiber, automobile, food and other industries.

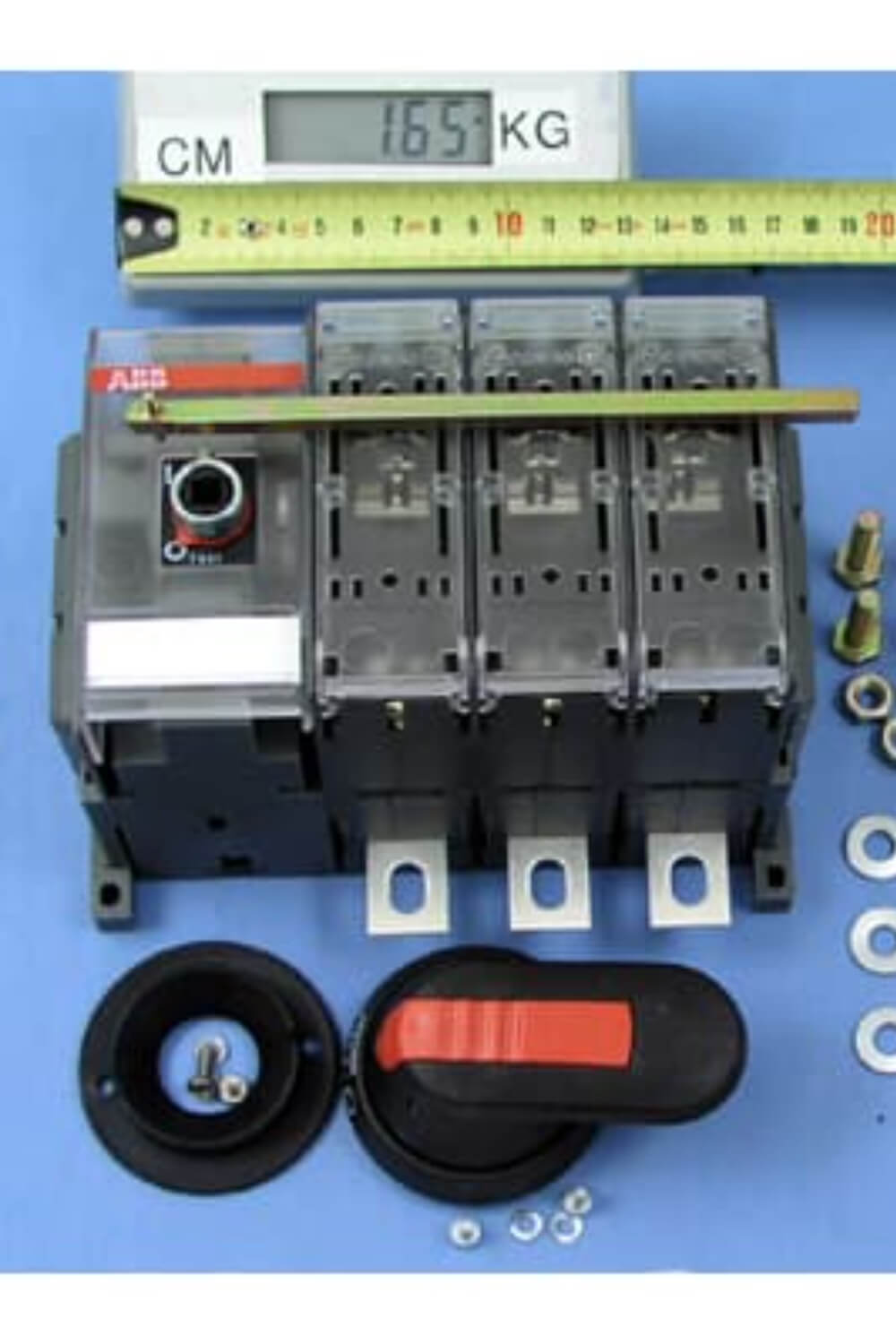

Links: 1sca022657r8950 3BSC610055R1

Pre: Delta Green Building +1! New EMEA off... Next: Glued Process of Industry Robot