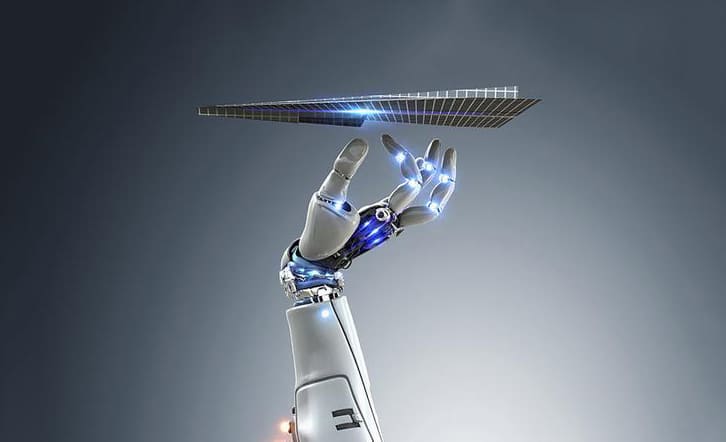

Glued Process of Industry Robot

Product introduction:

The robot gluing workstation is a robot application system developed by the Robot Center.

It mainly includes robots, glue supply system, glue application table, workstation control system and other peripheral supporting equipment. In order to improve the reliability of the system, the robot and the glue supply system in the gluing workstation generally adopt foreign products. According to the needs of users, our institute designs and manufactures the workbench, control cabinet and peripheral supporting equipment, and completes the gluing system. integrated. The workstation has a high degree of automation and is suitable for multi-variety and mass production. It can be widely used in industries such as automobile windshields, automobile and motorcycle lights, building materials, doors and windows, and solar photovoltaic cell gluing.

Main technical indicators of the headlight robot gluing workstation:

The auto lamp robot gluing workstation is mainly composed of robots, gluing machines, gluing workbenches, control cabinets and other equipment.

Robot:

The automation institute can select the robot brand according to the user’s requirements, and determine the robot specification and model according to the user’s product size. The repetitive positioning accuracy of the robot is ≤0.1mm, and the working speed of gluing is 150-250mm/s.

The robot has 6 control axes, which can flexibly generate any spatial trajectory and complete various complex glue laying actions. Coupled with its fast, stable movement and high repeatability, it can fully guarantee the production rhythm requirements, and ensure the uniformity of the rubber strips, so that the product quality is stable.

Glue supply system:

The glue supply system of the robot gluing workstation has two glue supply methods: cold glue and hot melt glue. The Automation Institute can configure the glue supply system according to the requirements of different customers. The glue supply system can be connected with the action of the robot to correctly complete the glue distribution and glue supply actions.

Gluing workbench

The structure of the gluing workbench mainly includes:

- Reciprocating double-station workbench

- Rotary double-station workbench

- Fixed double-station workbench

- Fixed single-station workbench

Our institute can design and manufacture various forms of worktables according to user requirements to ensure that the lamps are easy to install, accurate in positioning and reliable in operation.

Workstation control cabinet:

The design of the workstation control cabinet integrates the technical experience of many industries and adopts the latest electrical technology, and its performance index ranks first in the country. The system design adopts mature technology, the components adopt high-reliability equipment, and have passed strict purchase inspection, so the workstation control system has absolute reliability.

Main functions of the control cabinet:

- Part program number display and selection

- Coordination and interlocking of workbench, robot and glue conveying system

- Workbench working state selection

- With fault alarm and emergency stop function

- Counting function

User benefit analysis:

(1) High degree of automation, high production efficiency and large output.

(2) Reliable operation, high gluing precision and stable product quality.

(3) Save manpower, save materials, and reduce production costs.

(4) Improve the working environment and meet the requirements of environmental protection.

(5) When the output increases, there is no need to increase manpower, but only increase the working hours of the robot.

Links: 3bse069052r1 3bse013235r1

Pre: Transmission Lines of Industry Robot Next: Welding Process of Industry Robot