SICK interviews | Sensing helps intelligent manufacturing, innovation leads the future

As one of the world’s major Industrial powers and the initiator of “Industry 4.0”, Germany has produced a large number of industry “hidden champion” enterprises. Among them, the 76-year-old SICK (the Chinese brand is “Si Ke”) group is one of the typical representatives. SICK is committed to providing excellent industrial sensor application solutions for factory automation, logistics automation and process automation. Since entering the Chinese market in 1994, after nearly 30 years of development and accumulation, SICK has now become an influential supplier of smart sensor solutions in the Chinese market. Its products, system solutions and technical services have not only won Chinese users The wide recognition of China’s manufacturing industry has also played an important role in promoting the rapid development of China’s manufacturing industry and accelerating the digitalization and intelligentization of China’s manufacturing industry.

In order to have a more comprehensive understanding of SICK’s development strategy and future development plan, Dr. Huang Pei, editor-in-chief of e-works, interviewed Mr. Ding Boxiang, Deputy General Manager of SICK China Sales in September 2022, and asked Mr. Ding to discuss SICK’s development history, products and solutions. In-depth exchanges were conducted on the plan, as well as the development strategy of the Chinese market.

(Click on the poster to view the live replay)

01 Independence, innovation and leadership, to practice Industry 4.0 with intelligent sensing technology

At present, the era of intelligent manufacturing has come, and many manufacturing enterprises are actively promoting intelligent transformation and digital transformation to adapt to the new requirements and new changes in the new era, and intelligent sensors serve as the “eyes” and “ears” for collecting data, and The brain and heart of high-end manufacturing, process control, and networking operations are an important part of this wave of industrial upgrading and the key foundation and support for the realization of Industry 4.0. In recent years, with the in-depth advancement and implementation of Industry 4.0 practice, the application scope of smart sensors is constantly expanding, and they play an important role in various levels such as auxiliary systems, quality control, safety, flexible automation, predictive maintenance, and traceability. . As a leading manufacturer in the global sensor field and one of the initiators of the concept of Industry 4.0, SICK continues to practice with more advanced intelligent sensing technology and application solutions to support the promotion and realization of Industry 4.0.

SICK was established in 1946, the company name is taken from the surname of the founder Mr. Erwin Sick (Erwin Sick), the headquarter is located in the city of Waldkirch (Waldkirch) in southwestern Germany. After more than 70 years of development, SICK now has more than 50 branches, branches and representative offices around the world, with more than 11,000 employees. In 2021, the group will achieve an annual revenue of about 2 billion euros.

Among them, “independence, innovation, leadership” is the driving force for SICK to achieve sustainable and rapid development. “Independence” not only refers to the independence of enterprises in thinking and action, management, sales and R&D, legal and financial, but also emphasizes not being affected by external factors and focusing on leading the market in sensor products and solutions; “Innovation” emphasizes foreseeing For future development, we will develop new markets with products and solutions; “Leading” means clearly leading the global market with local competitiveness, focusing on the long-term, and emphasizing the creation of excellent customer value.

According to Mr. Ding, since its establishment, SICK has focused on the development, production and marketization of sensors, systems and services used in industrial automation technology, and has continuously improved and innovated in technology research and development and manufacturing, and has created many sensors in the field. a “first”.

For example, in 1952, SICK launched the first safety light curtain on the market at the 2nd Hannover International Machine Tool Trade Fair for personal safety protection of operators such as machine tools and punches;

In 1956, the market’s first photoelectric exhaust gas detector developed by SICK was put into use, mainly for safety and environmental monitoring;

In 2010, SICK launched the first color high-speed 3D camera Color Ranger E on the market, which can be applied to the quality inspection of PCB boards, steel plates, rails, plates, tires, etc.;

In 2018, SICK launched Outdoor Scan 3, the first outdoor security scanner on the market, which enables safe human-machine collaboration outdoors and breaks the boundaries of security automation.

Figure 1 SICK color high-speed 3D camera Color Ranger E

With the introduction of strategic plans such as Industry 4.0, intelligent manufacturing and industrial internet, the industrial automation and sensor industries have ushered in new opportunities for development. SICK regards the intelligence, innovation, independence and leadership of sensors as the core pursuit goals, and continues to increase Great efforts will be made to help the development of intelligent manufacturing in the fields of intelligent sensing, security protection, quality monitoring, tracking and traceability. In fact, SICK realized early on that the tasks performed by sensors are no longer limited to simply collecting data and information, but will become an important basis for building the factory of the future. To this end, SICK put forward the concept of “Sensor Intelligence (smart sensor expert)” in 2004 and established it as the company’s development concept, which fully reflects SICK’s forward-looking.

Up to now, SICK has formed a very complete product structure and has a competitive advantage in the breadth and depth of sensor products. According to Mr. Ding, the current SICK sensor product line has covered basic photoelectric sensors such as photoelectric switches and proximity switches, safety sensors (such as safety gratings, safety scanners), encoders, automatic identification and measurement (barcode/RFID/laser) scanning, laser ranging, etc.), machine vision and motion control products. In terms of software and digital services, SICK has also created an open software platform and ecosystem AppSpace for users, which can define hardware functions with software; while Integration Space is more focused on digging deep into the value of data, providing customers with optimized work/process Process efficiency to continuously improve productivity, intelligent digital services. In addition, SICK has also developed a series of application software based on industry customer needs and pain points.

Moreover, while providing a variety of smart sensor products, SICK also focuses on providing customized one-stop smart sensor system solutions for customers in the three major business areas of factory automation, logistics automation and process automation according to customer needs.

Factory Automation:SICK is mainly for the automotive industry, consumer goods industry, pharmaceutical industry, machinery manufacturing, 3C electronics, semiconductors, photovoltaics and other sub-industries, providing non-contact sensors and camera systems, encoders, and measurement systems for control manufacturing , packaging and assembly processes, undertake quality assurance work and ensure mechanical safety. In Mr. Ding’s words, SICK sensors can basically be seen wherever there is factory automation, but they play different roles, including safety protection, measurement, positioning, monitoring and monitoring, identification, detection, etc.

For example, 80% of the manufacturing plants of the world’s mainstream automobile brands use SICK products to realize the safety protection of the production line. In the 3C electronics industry, SICK’s 3D vision products are widely used in mobile phone parts inspection, electronic component inspection, glue circuit inspection, connector inspection and other scenarios, becoming the “gatekeeper” of product quality.

Logistics automation:SICK focuses on industries and fields such as airports, industrial vehicles, building management and building security, ports, express services, transportation, mobile Robots, etc., using intelligent sensors to improve the efficiency, speed and reliability of sorting, picking and warehousing processes, design and optimize the entire process. logistics chain.

According to Mr. Ding, about 70% of airport baggage sorting systems in China and around the world use SICK’s tracking and identification technology; China’s top ten AGV/AMR manufacturers are basically using SICK’s sensor products as core components. Moreover, in unmanned terminals such as Shanghai Yangshan Port and Qingdao Port, SICK’s products play an important role in accurate positioning and collision protection, which effectively guarantees operational safety and effectively improves port throughput.

Process automation:SICK mainly provides sensors and customized systems and services for analysis and process measurement technology, providing gas analysis, One-stop analysis and measurement system solutions for dust measurement, flow rate measurement, and level measurement.

Moreover, with the deepening of digitization and intelligence, the market demand for smart sensors and their solutions is increasing day by day. SICK is also constantly improving and perfecting its own smart sensor technology solutions, and is committed to providing customers with faster services. , and create real value.

02 Develop new energy field, sensor technology empowers industrial upgrading

Today, with the increasing demand for energy and the increasingly prominent energy crisis, actively advocating the concept of green, low-carbon and sustainable development, making full use of and developing new clean and green energy, and realizing low-carbon emission reduction has become my country’s carbon peak. , an important pathway to the carbon neutrality “two-carbon” goal. This also makes the new energy vehicle industry usher in the spring of development, and the shipments of new energy vehicles and power batteries have grown rapidly. In this context, leading power battery companies are expanding production capacity one after another, and at the same time put forward higher speed, higher beat, higher reliability and safety requirements for production lines and equipment. As a leader in the sensor industry, SICK has taken the field of new energy as a strategic development direction in recent years and has continued to make efforts, and is committed to providing intelligent sensor application solutions for scenarios such as intelligent production and detection of lithium batteries to help industrial transformation and development.

According to Mr. Ding, SICK China began to deeply cultivate the lithium battery industry in 2019, initially starting with standard sensors, providing standardized sensor products such as photoelectric switches, proximity switches, and positioning measurement for customers in the lithium battery industry. With the continuous deepening of industry applications, SICK realizes that because different customers have different requirements for production capacity, rhythm, speed, etc., the pain points and needs they face are also different. Sales”, and focuses on digitization, 3D vision, automatic code reading and identification, liquid level measurement, security and other scenarios, and provides intelligent sensors and application solutions.

Digitizing:SICK integrates digital full-dimension into its own products and solutions. It can not only provide sensors to monitor real-time data for running automation systems, but also provide intelligent access to data for machine and equipment condition monitoring, predictive maintenance and process optimization, etc. , to help the transformation and upgrading of the lithium battery manufacturing industry. Taking the winding machine of lithium battery production equipment as an example, SICK not only provides sensor products such as color mark/color sensors, which provide strong support for intelligent identification and efficient production; it also provides sensor gateways to collect, store and transmit data from sensors, and Connected to the cloud, it can not only realize remote measurement status monitoring, but also remotely configure sensor parameters and perform pre-maintenance, laying a solid foundation for the realization of Industry 4.0.

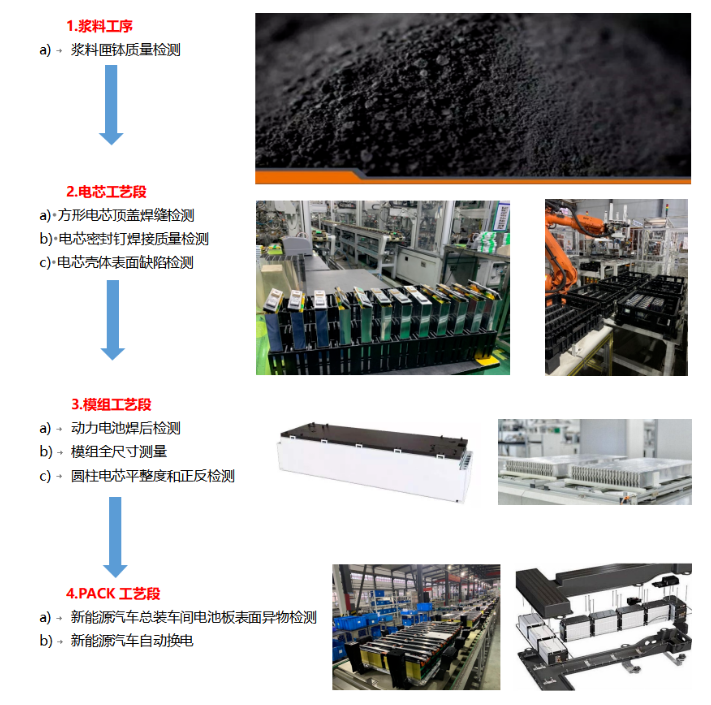

3D Vision:SICK’s 3D vision solution can cover the 3D inspection needs of multiple processes and stations for new energy power batteries from paste, cells, modules to PACK. For example, in the slurry process section, the quality inspection of the slurry lithium battery sagger can be provided; in the cell process section, the welding seam inspection of the square cell top cover, the welding quality inspection of the cell sealing nails, and the surface defect inspection of the cell shell can be provided; The module process section can provide power battery post-weld inspection, module full-size measurement, cylindrical cell flatness and positive and negative inspection. Automatic battery swap 3D guide. At the same time, SICK can also provide more ideal customized 3D inspection solutions according to specific visual field requirements and various complex working conditions to improve inspection efficiency and quality inspection results.

Figure 2 The application of SICK 3D vision in the power battery industry

Automatic code reading and identification:SICK provides a wide range of fixed-installed and mobile automatic identification products, which can be used for cell identification, assembly loading identification, etc., laying the foundation for ensuring smooth production processes, as well as achieving traceability and continuous quality improvement. For example, SICK LECTOR series barcode readers have powerful intelligent decoding algorithms, which can be used to solve the application of DPM (Direct Part Mark) barcode recognition such as batteries for new energy vehicles. It features easy integration, robustness and high read reliability, ensuring reliable identification of DPM barcodes in harsh environments, ensuring full traceability, and helping to achieve on-time and high-quality delivery of parts.

Level measurement:Lithium battery electrode slurry is the first process of lithium battery production, and it is also the most important link. During the process of adding chemicals and stirring the slurry, the liquid level needs to be controlled, which is also where SICK’s liquid level measuring sensors come into play. According to Mr. Ding, since the direction of stirring often changes during the slurry stirring process, the measuring rods of major brands of liquid level measuring sensors have experienced the problem of falling off of the measuring rods. For this reason, SICK focuses on customer pain points and needs. , An integrated liquid level sensor has been developed, which effectively solves the problem that the measuring rod often falls off.

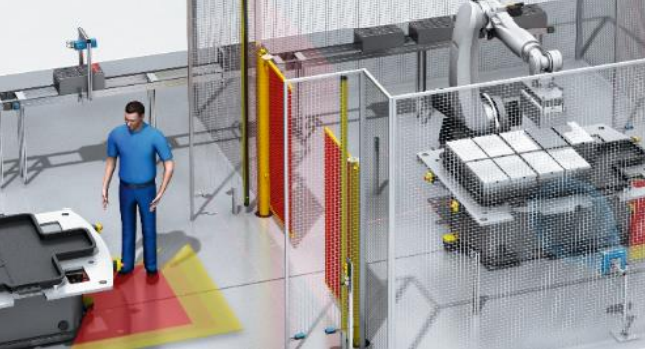

Safety:In the lithium battery industry, automated assembly lines, welding lines, logistics lines, as well as winding machines, liquid injection machines, industrial robots, etc., all have potential safety risks, and measures need to be taken to prevent personal injury to operators. SICK has a variety of safety products such as safety light curtains, safety PLCs, safety scanners, safety radio frequency switches, safety door switches, safety relays, etc., providing logistics and entry and exit protection for the lithium battery industry, winder and manipulator safety protection, liquid injection machine , safety door protection of assembly line and other safety protection solutions.

Figure 3 Logistics and entrance and exit security protection

Mr. Ding pointed out that while focusing on the five business scenarios and directions of the lithium battery industry, SICK also strengthened the coordination and cooperation of multiple teams including the sales team, cloud team, and visual business development team in the organization to better respond to customer needs. Today, SICK China has a dedicated visual team and cloud team to help the development of the lithium battery industry and customers, which is also the advantage of SICK compared to other competitors.

However, Mr. Ding also emphasized that new energy is a big concept, and lithium battery is only one of the important directions. Others include hydrogen fuel cells, sodium-ion batteries, etc., which are also the future development directions. SICK will also continue to pay attention to the development of these industries and fields, and provide smart sensor solutions.

03 Accumulation of profound industry experience, the key to winning the trust of customers

Since its establishment in 1946, SICK has gone through 76 years. In the past 76 years, SICK has always focused on the development of sensing technology, and has accumulated very rich experience in industrial applications.

On the SICK official website, SICK divides the industries it serves into more than 40 categories by industry application, including semiconductors, packaging, operation and installation technology, printing, batteries, electronic components, textiles, wind energy, machine tools, robotics manufacturing technology, home appliances Equipment, tires, wood, automotive and components, drives and controls, production logistics, stone, ceramics, glass, food and beverages, digital transformation, plastics and rubber, solar energy, healthcare manufacturing, consumer healthcare, warehousing and conveying technology, Ports, industrial vehicles, airports, building security systems, transportation, express and postal industries, shipbuilding, power generation, mining, metals and steel, oil and gas, etc., cover almost all aspects of industrial production and life.

In fact, SICK is familiar with the production process of various industries and has rich industry experience, which is the main reason why customers believe and finally choose SICK. According to Mr. Ding, in the past few years, SICK’s German headquarters has conducted a purchasing experience survey for global customers. The survey is divided into four dimensions: company and brand influence, industry experience, cost performance, product service and delivery. The final survey results show that among the reasons why customers choose SICK, industry experience accounts for the highest proportion, reaching 53%; company and brand influence, product service and delivery are next, accounting for 19%; cost performance accounts for 9%. This also fully shows that SICK has deep experience in different industries, which is the most valued by customers.

Mr. Ding also shared some examples of customers choosing SICK. For example, there was a customer who wanted to do sensor applications for port unmanned docks and AGVs. After searching for mainstream suppliers in the market, they finally chose SICK. Because SICK has rich application experience in the port industry, SICK sensors can be seen in almost all large unmanned docks and have been used in port applications for many years. People are used to using SICK sensors and will not take risks to replace them with other brands. Moreover, even though this year was affected by the Shanghai epidemic, orders surged but logistics was blocked, and SICK’s product delivery was delayed. Many customers would rather wait than easily switch to other brands.

Mr. Ding also admitted that from the survey of global customer purchase experience, the final survey results are still somewhat different from what he expected. He thought that the proportion of company and brand influence would be the highest, but SICK The highest proportion of industry experience. However, this also reminds that SICK still has a lot of room for improvement and improvement in terms of company and brand, product service and delivery, and cost-effectiveness. “We hope that the proportion of the four dimensions of company and brand influence, industry experience, product service and cost performance will be more balanced in the future, which is what we want most,” said Mr. Ding.

04 Deeply cultivate the Chinese market with a global vision and local services

SICK established the SICK China headquarters in Guangzhou in 1994, and has since entered the Chinese market. Over the past 28 years, SICK China, as one of the important branches of SICK in Asia, has established branches and offices in Shanghai, Beijing, Qingdao, Hong Kong, Suzhou, Shenyang, Chengdu and other places. institutional system and business network.

According to Mr. Ding, in recent years, SICK China’s performance has grown very rapidly. Even under the epidemic, SICK China’s performance has shown a rapid growth trend. In the view of e-works, the rapid growth of SICK China’s performance is mainly due to SICK’s global vision and localized services.

As a global sensor manufacturer from Germany, how to better serve Chinese local customers has always been the focus of SICK. In order to better serve Chinese customers, SICK has carried out a series of layouts in China.

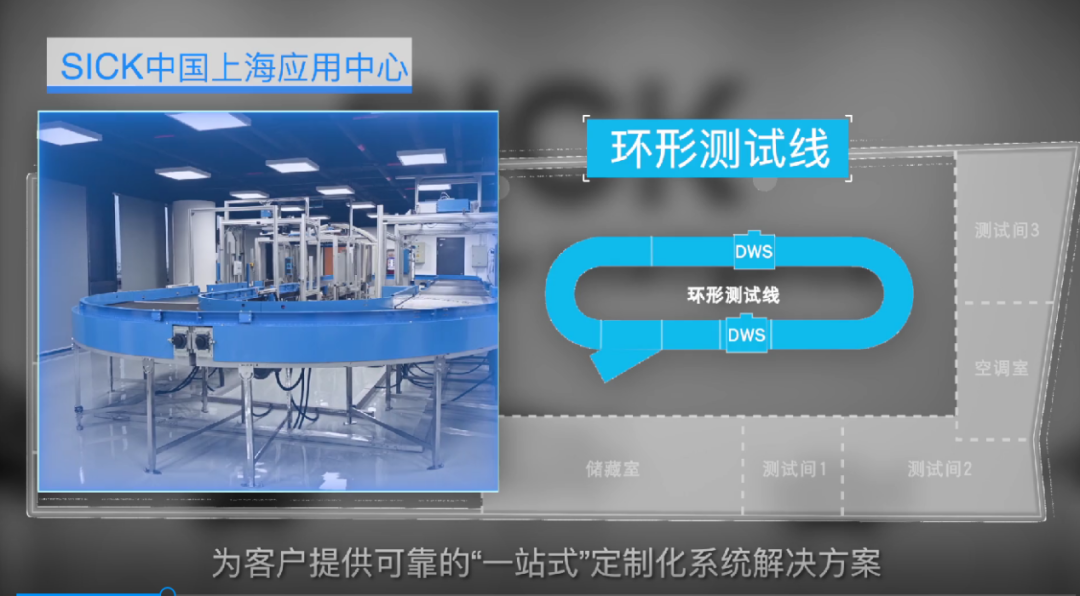

In 2011, SICK established the Shanghai Application Center, which is an important system product demonstration center and customer system training center of SICK in China. The R&D laboratory provides customers with reliable one-stop customized system solutions.

In 2016, SICK established the Shanghai Vision Lab, which was established under the background of the rapid development of China’s automation market, especially the growth of the vision business (especially 3D vision), which is mainly responsible for the vision products in the Chinese market. Landed R&D.

In 2018, SICK established an Asia-Pacific logistics center in Jiaxing, Zhejiang, serving China and the entire Asia-Pacific region to provide efficient logistics services.

In 2019, SICK also established Jiangsu SICK Sensor Co., Ltd. in Changzhou, Jiangsu. As the production center of SICK in China, Jiangsu SICK is another important strategic measure for SICK to realize localized operation, establish a foothold in China and connect with the world. Moreover, Jiangsu SICK will also become the second Industry 4.0 demonstration factory of SICK in the world after the 4.0 NOW Factory in Freiburg, Germany, to demonstrate SICK’s personal practice of Industry 4.0 for Chinese customers.

Figure 4 SICK China Shanghai Application Center

In addition, SICK China has autonomy in development strategy, which also enables SICK to understand and get closer to the Chinese market and user needs. According to Mr. Ding, SICK China, as a branch of SICK Group in China, will receive strong support from the German headquarters. However, from the perspective of future development and strategy, SICK China has full autonomy in its development, and SICK headquarters will not carry out too much development. many restrictions. The strategies developed by SICK China in recent years, such as AMR strategy, lithium battery strategy, 3D vision strategy, etc., are all strategies based on the demand insight of the Chinese market. To put it simply, SICK China seeks its own development strategy and direction based on the Chinese market and German products, and forms tailor-made solutions through local software and local integration to serve Chinese customers. This also enables SICK China to adapt to the needs and changes of the Chinese market in a timely manner, and to make self-adjustments in terms of products, systems, software, as well as personnel and structure, thereby helping the development of the industry and customers.

It is with its global vision and localized services that SICK is deeply rooted in the Chinese market, from initial product sales to complete solution services, from assembly production to customized R&D for local needs, to take root and grow in the Chinese market. Based on the current and future, SICK is committed to providing wider and more open solutions through an open ecosystem.

Mr. Ding said that SICK is committed to becoming a reliable supplier of hardware, software and solutions in the field of sensors in China. At the same time, SICK hopes to not only establish a simple buying and selling relationship with customers, but also achieve vigorous development together with customers. Therefore, the current and future focus of SICK is to build an open ecosystem around end users and realize the co-prosperity of ecosystem partners. This is SICK’s development vision in China, and it is also a very big difference between SICK’s development strategy in the Chinese market compared to the past. . SICK China will focus on the needs of the local market and customers, firmly adhere to the business model of product, system and service development, adhere to good cooperation with customers, partners and suppliers, jointly promote the development of China’s industrial automation market, and ultimately achieve a win-win situation and a win-win situation .

05 Postscript

Objectively speaking, the product category is rich, the quality is reliable, and the R&D innovation ability is strong. At the same time, it always focuses on the market and customers, actively embraces changes, continues to innovate, and provides localized and customized services, plus 76 years of industry experience accumulation and reputation. And brand accumulation is the main reason why SICK has always been at the forefront of the tide, has maintained an independent and leading position in the field of global smart sensors for a long time, and has overcome difficulties and developed rapidly in the Chinese market. According to Mr. Ding, with green and low carbon becoming the main theme of social development, intelligent manufacturing and robotics technology are developing rapidly, and the application of digital twins has broad prospects. SICK is also promoting the R&D innovation, implementation and application of intelligent sensors and solutions in related fields. e-works also sincerely looks forward to seeing SICK in more fields in the future; SICK’s future development pace can also go faster and more stable.

The Links: 3HNA006146-001 3HAC027641-001

Pre: Intuitive Fosun’s “domest... Next: Why can “robots” with the...