Features of Industrial Robot

The industrial robot proposed by Daval has the following characteristics: the servo axis of the CNC machine tool is connected with the linkage mechanism of the remote manipulator, and after the preset manipulator action is programmed and input, the system can operate independently without human assistance. . This kind of robot can also accept teaching to complete various simple repetitive actions. During the teaching process, the manipulator can pass through each position of the work task in turn. These position sequences are all recorded in the memory. During the execution of the task, each part of the robot The joints reproduce the above positions sequentially under the servo drive, so the main technical functions of this robot are called “programmable” and “teaching and reproduction”.

Some industrial robots launched in the United States in 1962 have roughly similar control methods to CNC machine tools, but their appearance is mainly composed of human-like hands and arms. Later, industrial robot systems with vision sensors, which can recognize and locate, appeared.

The salient features of industrial robots are as follows:

Programmable. A further development of production automation is flexible start-up. Industrial robots can be reprogrammed according to the changing needs of their working environment, so they can play a very good role in the flexible manufacturing process of small batches and multiple varieties with a balanced rate, and are an important part of the flexible manufacturing system.

personification. Industrial robots have human-like walking, waist turning, big arms, forearms, wrists, claws and other parts in the mechanical structure, and there are computers in the control. In addition, intelligent industrial robots also have many “biosensors” similar to humans, such as skin-type contact sensors, force sensors, load sensors, visual sensors, acoustic sensors, language functions, etc. Sensors improve the ability of industrial robots to adapt to the surrounding environment.

Versatility. In addition to specially designed professional industrial robots, general industrial robots have good versatility when performing different tasks. For example, different tasks can be performed by replacing the end manipulator (claw, tool, etc.) of the hand of an industrial robot.

Industrial machine technology involves a wide range of subjects, which can be summed up as a combination of mechanics and microelectronics – mechatronics technology. The third-generation intelligent robot not only has various sensors for obtaining external environmental information, but also has artificial intelligence such as memory ability, language understanding ability, image recognition ability, and reasoning and judgment ability. These are the applications of microelectronics technology, especially computer technology. applications are closely related. Therefore, the development of robot technology will definitely drive the development of other technologies, and the development and application level of robot technology can also verify the development level of a country’s science and technology and industrial technology.

Today’s industrial robot technology is gradually developing towards the direction of walking ability, multi-perception ability, and strong adaptability to the working environment. Currently, the United States and Japan are the countries that have influence on the development of international robot technology. The United States is still in the leading position in the comprehensive research level of industrial robot technology, while the industrial robots produced by Japan rank first in the world in terms of quantity and type.

Technology*Industrial robots integrate advanced manufacturing technologies such as precision, flexibility, intelligence, and software application development. Reducing resource consumption and environmental pollution is a high level of industrial automation.

Technology upgrade Industrial robots and complete sets of automation equipment have technical characteristics such as fine manufacturing, fine processing and flexible production. An important means of digitization, automation, networking and intelligence.

Wide range of applications Industrial robots and automation complete sets of equipment are key equipment in the production process, which can be used in manufacturing, installation, testing, logistics and other production links, and are widely used in automobiles and auto parts, construction machinery, rail transit, low-voltage electrical appliances, Electric power, IC equipment, medicine, tobacco, finance, medicine, metallurgy, printing and publishing and many other industries have a wide range of applications.

Strong technical comprehensiveness The industrial robot and automation complete set of technology integrates and integrates multiple disciplines and involves many technical fields, including industrial robot control technology, robot dynamics and simulation, finite element analysis of robot construction, laser processing technology, Advanced manufacturing technologies such as modular program design, intelligent measurement, modeling and processing integration, factory automation and fine logistics, etc., are highly comprehensive in technology.

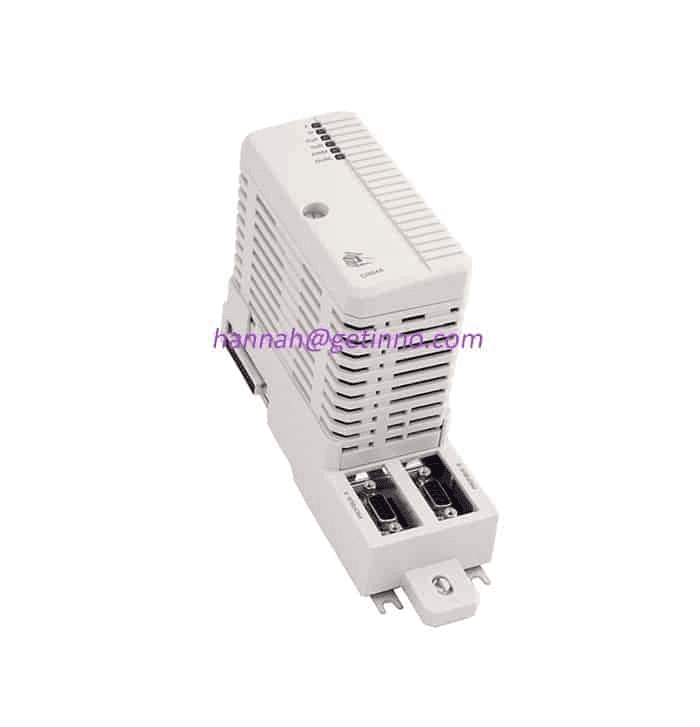

Links: 3bsc950193r1 3bse008508r1

Pre: Huawei’s Ark compiler framework... Next: Composition of Industry Robot