Analyze the difficulties and methods of high-quality development of the manufacturing industry in 2019

Recently, among the key tasks for 2019 proposed by the Central Economic Work Conference, “promoting the high-quality development of the manufacturing industry” was given the top priority.

At the symposium held by the Political Research Office of the National Development and Reform Commission recently, representatives from manufacturing enterprises, experts and scholars, and the heads of relevant departments of the National Development and Reform Commission focused on the above topics to discuss the current pain points, difficulties and high-quality development of my country’s manufacturing industry. In-depth discussion was carried out.

Although my country has become a major manufacturing country in the world,“Big but not strong”, “Complete but not excellent”The problem is still outstanding. Delegates believed thatTo promote the high-quality development of the manufacturing industry, we must focus on strengthening the foundation, making up for shortcomings, focusing on innovation, cultivating talents, and optimizing the environment, giving play to the decisive role of the market in resource allocation, and forming a joint force to promote the high-quality development of the manufacturing industry.

What are the pain points and difficulties of enterprises

When it comes to the problems in the development of the manufacturing industry, companies have the most say.

Every time around ‘618’ and ‘Double 11’, a large number of workers resigned. These young people in their 20s are more willing to be courier brothers, because they can earn ten thousand or twenty thousand yuan in one month…

Yan Feilong, chief engineer of Xizi United Holdings Co., Ltd. from Zhejiang, has learned a lot about this: the training cycle of Industrial workers is long, and a good technician cannot be trained within a few years, but the stability of employees is a big problem!

Not only front-line workers, but also the manufacturing industry is becoming less attractive to high-end talent.

Zhang Yuxian, director of the Economic Forecasting Department of the State Information Center, admitted that many high-tech talents do not apply what they have learned to manufacturing, but “use professional skills to play finance.”

Some people in the capital market are eager to make quick money. If a manufacturing entrepreneur works hard for a year, it is better to make a lot of money by flipping a house. Who would go to the manufacturing industry? A slow company is not because it wants to be slow, but because its manufacturing projects often have a long investment cycle; a stupid company is not because it is stupid, it just wants to develop steadily and does not want to go wrong. These small companies actually have technological content, and may produce disruptive innovative technologies in the future.

Yan Feilong said that he hoped that governments at all levels could support more slow, stupid and small companies.

In fact, financing difficulties and innovation difficulties are still the common troubles faced by many manufacturing enterprises.

Liu Xingguo, a researcher at the China Enterprise Confederation, said that bank loans often do not match the production cycle of enterprises, resulting in a large number of small and medium-sized enterprises paying higher costs in order to obtain funds, which not only affects the development of small and medium-sized enterprises, but even becomes a problem for survival.

In the field of research and development, the lack of key core technologies has not been fundamentally improved.

What we felt most deeply during the enterprise research is that many enterprises have the situation that equipment manufacturing and core components are controlled by others.

The experience of Fu Baozong, director of the Industrial Research Office of the Industrial Institute of the China Academy of Macroeconomics, resonated with the delegates.

Chen Daquan, deputy general manager of Weichai Holding Group, said frankly that at present, the market has higher and higher requirements for engine performance, but some key components have to be imported from abroad. Although there are similar products in China, they are relatively poor in reliability and consistency. Some, key components still have constraints on us.

Hu Shujie, senior vice president of Great Wall Motor Co., Ltd. bluntly said: “At present, the high-quality development of the manufacturing industry needs to solve the problems of dependence on imports of high-performance chips, lack of independent research and development of industrial software, insufficient self-sufficiency rate of high-end CNC machine tools, and lack of performance and quality of key basic components. “

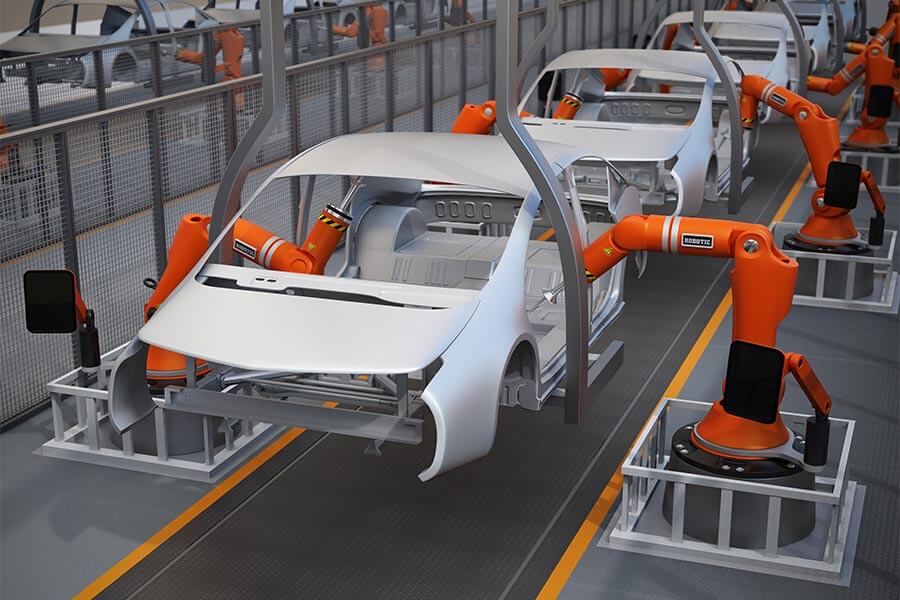

Although Great Wall Motor’s R&D and manufacturing capabilities have reached the level of foreign brands, it still needs to import industrial Robots, CNC machining machines and other equipment from developed countries to ensure the machining accuracy and quality of its products.

How to look at the advantages and disadvantages of manufacturing

Since the reform and opening up, my country’s manufacturing industry has achieved sustained and rapid development. At present, a complete, independent and complete manufacturing system has been established. On the whole, although the scale of the manufacturing industry ranks first in the world, the problem of being large but not strong is still prominent.

Liu Xingguo, who has been tracking and researching China’s top 500 companies for a long time, uses “five lows and one small” to describe the overall status of my country’s manufacturing industry.

The “five lows” are that the R&D investment is obviously low, the value-added rate is very low, the profit margin is obviously low compared with foreign countries, the internationalization rate is low, and the per capita output rate is low;

“One less” means that there are fewer internationally renowned brands in China’s manufacturing sector.

The average value-added rate is only about half of that of the United States and Germany, indicating that the overall manufacturing industry in my country is still dominated by simple and superficial processing, and the links with high added value are less involved;

Profit margins in manufacturing are significantly out of balance compared to some other industries;

The low rate of internationalization indicates that most manufacturing enterprises have not yet participated in internationalization.

Zhang Yuxian believes that,The first thing that the manufacturing industry faces is that the “four foundations” are not strong, that is, there is an urgent need for improvement in basic raw materials, basic industries, basic components, and basic technologies.

The second is the core technology problem, but the most fundamental is the talent problem, which is also the key to breaking through the “stuck neck” problem of the core key technology.

In Fu Baozong’s view, my country’s manufacturing industry has now entered the threshold of “climbing over the hurdle, if not advancing, it will retreat”, and it is facing “two-way attack” at home and abroad.

On the one hand, developed countries promote the return of manufacturing industries, implement trade barriers, and contain my country’s mid-to-high-end manufacturing industries. Some Southeast Asian countries also use cost advantages to catch up with my country’s manufacturing industries;

On the other hand, my country’s manufacturing industry is constantly faced with unfavorable factors such as high production costs and declining demographic dividends.

“Challenges are increasing, but there are still opportunities for my country’s manufacturing industry.” Zhang Yuxian said that the trend of globalization is irreversible, and the normal operation of the global value chain will not be disrupted.

In the environment of reform and opening up, we can completely catch up with or meet the third technological revolution, which is a very big opportunity.

Internally, we have the largest consumer market, complete industrial facilities and strong infrastructure, and the world’s largest number of skilled workers and mid-to-high-end R&D personnel, which is a new talent bonus. In addition, we are also implementing an innovation-driven strategy, which can completely change lanes and overtake in certain areas.

How to turn to high-quality development

Experts point out thatTo promote the high-quality development of the manufacturing industry, the key is to play the decisive role of the market in resource allocation.

At the same time, the government should play a better role in strengthening national strategic leadership, establishing a sound innovation ecosystem, optimizing the industrial structure, and creating a fair and orderly market environment.

The high-quality development of the manufacturing industry as I understand it is the development that reasonably meets the normal material needs of consumers. Efforts should be made to maintain a reasonable ratio of high, medium and low levels within the manufacturing industry to meet the needs of different consumer groups, not the best, but the right.

Zhang Yuxian said that there is no distinction between consumption and demand itself, and neither is the industry that meets consumption and demand.

How does the business do it?

To maintain the long-term and healthy development of the enterprise, it is still necessary to insist on innovation-driven, quality-oriented enterprise, and talent-oriented.

Chen Daquan believes that it is necessary to seize the opportunities of digitalization and intelligence to open up the links of R&D, design, manufacturing, and delivery of traditional enterprises, and improve the efficiency of industrial collaboration.

In terms of breaking through core and key technologies, it is necessary to combine “bringing in” and “going out”, combining absorption, digestion and re-innovation, and actively integrating into the global scientific and technological innovation system.

Last year, Haier Group’s global revenue reached 241.9 billion yuan, and in the first 10 months of this year, it reached more than 220 billion yuan, with double-digit growth in profit and sales revenue.

Liu Zhenyu, general manager of industrial planning and policy of Haier Group, said that the current changes in domestic and foreign environments have little impact on Haier, mainly due to Haier’s adherence to two main lines:

One is based on the change of the times, from the introduction of foreign technology to the integration of global resources, and then to the layout of the global market, and always be an enterprise of the times;

The other is based on the value of people. Through “Rendanheyi”, employees can create their own value in the process of creating user value. As the manufacturing industry develops towards high quality, enterprises can focus on the transformation and reconstruction of strategy, organization and mechanism.

What should the government do?

Fu Baozong believes that in the current climbing stage,The government is mainly to build a platform, optimize the environment, build an ecology, make up for shortcomings, and stabilize expectations.

The market system is like the sports selection mechanism of the Olympic stadium. The government does not need to choose who is the best. As long as the entry criteria and exit mechanism are well designed, the judges are selected, and the rest will naturally be divided.

The Links: 6AV2144-8GC10-0AA0 TB815

Pre: Compared with a dog’s nose, a r... Next: The successful launch of the intellig...