Tianchuang robot opens more possibilities for intelligent inspection

With the gradual integration of artificial intelligence with traditional industries, the internet of Things, cloud computing, and 5G technologies have brought considerable economic and social benefits to enterprises, and promoted the restructuring and upgrading of various industries. The adjustment of China’s Industrial structure has allowed inspectionrobotalso ushered in rapid development.The power sector led by the State Grid Corporation of China has continuously introduced intelligent power grid inspection Robots to improve the traditional manual inspection of substations and distribution stations.Digitizingand improve the overall intelligent operation level of the power grid system. As the application in the power industry continues to mature, inspection robots have begun to expand more scenarios and protect the safety of more industries.

Recently, OFweek interviewed Tianchuang Robot, one of the representative enterprises of intelligent inspection robots, to gain insight into the future of inspection robots in terms of product technology, application fields and development trends.

From motion control to intelligent inspection

The era of intelligence has kicked off, and artificial intelligence technology, automatic identification technology and the robot industry have developed more rapidly. Robot inspection has become one of the three main inspection methods in the industrial field. In terms of application, electric power is a typical industry in which inspection robots have been applied earlier and have a wide range of applications. Tianchuang robots also started from the electric power industry and gradually developed and expanded.

At the beginning of its establishment in 2011, Tianchuang’s core business is motion control, which is also an important manifestation of the competitiveness of inspection robots.Tianchuang’s inspection robot products inherit this technical advantage, and on this basis, form a power distribution room rail-mounted inspection robot, a pipe gallery inspection robot, an indoor wheeled inspection robot, an outdoor wheeled inspection robot, Rich product lines such as belt conveyor inspection robots, explosion-proof wheeled inspection robots, etc.After several years of development, motion control has also become the core underlying technology of Tianchuang robots. After further introduction of AI algorithms, it has been continuously deepened on the application side.

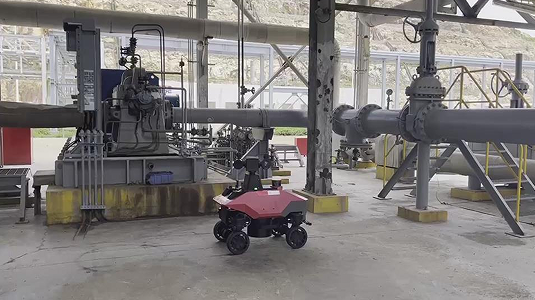

The application of Tianchuang inspection robots started from the nuclear power plant scenario, and launched many targeted applications for power generation scenarios such as high-voltage conveying vehicles. In addition, the inspection of belt conveyors in coal power plants has spread to ore transportation lines such as ports and terminals. Make products well through one scene, and then implement them horizontally to similar scenes. Relying on this development model, Tianchuang has penetrated into wind power plants from traditional power plants with the in-depth development of the entire power industry. Mining, metallurgy, rail transit, tunnels, aquaculture and many other fields have driven the two-way development of itself and the industry.

Not only robots, but also intelligent operation and maintenance

To judge the strength of the inspection robot, reliability and fault diagnosis algorithm are important indicators. The former requires stable product performance, and the latter requires a lot of industry experience and samples, which Tianchuang happens to have. Thanks to the advantages and technical strength of entering the game earlier, Tianchuang has accumulated a lot of practical experience, has rare data in the industry, and finally allows the data to serve customers. Taking coal power plants as an example, the data on the tearing frequency of coal conveyor belts obtained by Tianchuang is the accumulation of long-term experience, which enables Tianchuang to have a deeper understanding of customer scenarios and a more accurate grasp of needs.

As far as the product itself is concerned, the self-research rate of Tianchuang’s machines has reached 95%.sensorIn addition to the use of industry representative brands, other overall components are developed by Tianchuang, and even the tires are designed and moulded by Tianchuang. R&D personnel account for nearly 50%, giving Tianchuang strong technical advantages. On the basis of self-developed hardware, and relying on the deployment experience of different scenarios, Tianchuang has created its own software platform. For different applications, it integrates all modules on one platform. Customers only need to select the functions they need. Relevant applications are available for ease of use.

Unlike simply introducing robots, Tianchuang’s expert team can open up the operation and maintenance links in the entire scene. Therefore, Tianchuang does not define itself as a robot company, but a company that provides equipment operation and maintenance management services in the energy industry— —Using robots as a carrier to collect data, perform fault detection, analysis and even pre-judgment on equipment, bringing users a reliable and economical complete set of intelligent inspection solutions.

Technical strength opens up future competitiveness

In addition to common indoor inspections, at present, for harsh and extreme outdoor environments, Tianchuang has also brought its own advantageous products, which have given robots the ability to overcome obstacles and climb hills through innovative technologies. The ability to overcome obstacles is the embodiment of Tianchuang’s hardware advantages. The chassis of the product adopts four-wheel and twelve-wheel drive, and each wheel can be lifted independently. The height of the lift can be judged through torque detection, so as to achieve a smooth transition and cleverly overcome obstacles. In terms of climbing, the four-wheel and eight-wheel drive technology can help the robot to climb a 40° slope smoothly.

Of course, Robotic products still have to move towards the goal of intelligence.Tianchuang believes that the current AI industry is still in the era of weak artificial intelligence, and inspection robots still rely on preset scripts to perform operations and cannot make decisions like the human brain..To this end, Tianchuang creatively opened up a development path for remote teleoperation, and equipped the inspection robot with a remote controlrobotic armand the specific decision-making power is still handed over to skilled manual workers in the background., at this stage, the automation of inspection work can be guaranteed, and some emergencies can also be accurately handled. At present, Tianchuang is conducting related technical cooperation with Southeast University, and some projects have begun to invest in research and development.

Based on this teleoperation technology, Tianchuang has won many scientific and technological awards including the “First Prize of Artificial Intelligence Science and Technology Progress” and “First Prize of Jiangsu Province’s Science and Technology Progress”. In the future, Tianchuang will further polish its technology. Mature and then put on the market.

While carrying out technology research and development, Tianchuang is also committed to bringing good products to a larger market. Strategically, Tianchuang is developing into 8 major scenarios including electric power, rail transit, metallurgy, petrochemical oil and gas, mining, aquaculture, and wind power. It expands out through 8 marketing divisions, provides targeted solutions, improves work efficiency and accuracy, and deploys industrial brains that can process data immediately at industrial sites.

In the future, on the product side, Tianchuang will further build a platform strategy and further improve its software, algorithms and scenario-based diagnostic models. In addition, the remote operation technology will also be further developed to give the inspection robot basic operating capabilities. We also look forward to seeing the release of related products in the near future.

The Links: 1SAP240000R0001 3BSE028586R1 ELECTRONIC

Pre: Pilz: Never take the safety of indust... Next: New product release | KUKA AMR family...