Pilz: Never take the safety of industrial burners seriously

Heating is an indispensable part of some Industrial production processes. Applications such as metal heat treatment, glass melting, food baking, grain drying, fiber depilation, and oven baking all rely on heating.

Industrial burners fueled by gas/liquid are the mainstream equipment used in heating today. The safety of industrial burners is related to the reliability, efficiency and stability of the entire production process, so don’t take it seriously!

European standards related to industrial burners

The European standard EN 746-2 specifies the safety requirements for combustion and fuel handling systems, which must meet at least the following three points to prevent accidents:

- Prevent unintentional release of unburned fuel

- The correct ignition time of the burner

- Switch off the fuel supply in the event of a related fault

In addition, in Europe, there are other standards with relevant safety requirements for industrial burners, such as:

- DIN EN 298:2012-11 Automatic combustion control systems for burners and appliances burning gas or liquid fuels

- DIN EN 50156-1:2016-03 Electrical equipment for combustion furnaces and auxiliary equipment – Part 1: Requirements for application design and installation

- DIN EN 50156-2:2016-03 Electrical equipment for combustion furnaces and auxiliary equipment – Part 2: Requirements for the design, development and type approval of safety equipment and subsystems

The safety “patron saint” of industrial burners

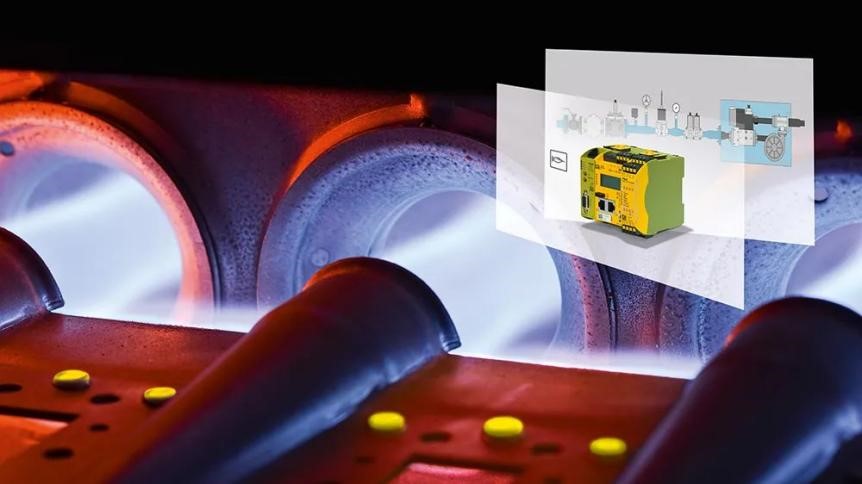

PNOZmulti programmable modular safety system is one of the most popular safety control products of PILZ company. In this series, there are safety modules specially designed for industrial burner control, which can be described as the “artifact” of industrial burner safety monitoring.

A PNOZmulti system can control up to 12 industrial burners simultaneously and is suitable for the following types of oil/gas burners: direct/indirect fired main burners (with combined flame monitoring/independent flame monitoring available), direct/indirect fired main burners Slave burner (can be combined with combined flame monitoring/independent flame monitoring).

The accompanying software tool PNOZmulti Configurator provides the TÜV-certified “Burner Management” function block for safe monitoring of safety steps, combustion air pressure, ignition signal, flame status, external mixing controller and tightness, as well as combustion The safety valve, ignition valve, exhaust valve, igniter and blower of the device are used for safety control. Safety levels up to EN ISO 13849-1 PL e Cat. 4 and IEC 61508 SIL CL 3.

The base module PNOZ m B1 Burner (772102) is specially developed for industrial burner applications based on EN 298, EN 50156, NFPA 85, NFPA 86, UL 60730 and has CE, TÜV, cUL listed certificates. Up to 12 I/O modules can be expanded on the right side. In addition to the functions related to burner management, it can also monitor other safety functions, such as emergency stop buttons, safety doors, safety light curtains, etc. on the equipment. Users only need to This system can realize the safety monitoring of the entire burner, and the application is very flexible.

In addition, the special safety I/O extension module PNOZ m EF 4DI4DORD (772145) integrates a different safety relay output, which is especially suitable for controlling the safety valve of the burner.

The PNOZmulti programmable modular safety system is suitable for situations where multiple industrial burners need to be controlled at the same time. It is a cost-effective burner management safety control. Because it can also integrate other general safety functions, it makes on-site safety applications more Flexible and complete.

The Links: TB840/3BSE021456R1 3BSE018173R1

Pre: Zhangye Zhizao helps the national ant... Next: Promote the development of intelligen...