The number of industrial robot companies ranks first in the country, and the industrial robot industry in Jiangsu Province is counted

introduction

In order to meet the real needs of high-quality development faced by my country’s current manufacturing industry, the segmented track of Industrial Robots must not be bypassed. For a long time, industrial robots have been regarded as the “pearl at the top of the manufacturing crown”. Its R&D, manufacturing, and application are important symbols to measure a country’s technological innovation and high-end manufacturing level.

Despite the rough road and difficult start, in the continuous struggle of generations of scientific research workers, industry enterprises, and entrepreneurs in our country, from the 1980s when my country independently developed the first industrial robot, to today’s Industrial Robot application field in my country It has covered 52 industry categories and 143 industry categories such as automobiles, electronics, metallurgy, light industry, petrochemicals, and medicine. Although many difficulties still need to be overcome, in just the past forty years, my country’s industrial Robot Industry has basically formed a whole industrial chain system from parts to complete machines to integrated applications.

As a traditional industrial province, Jiangsu, in the context of a new round of global technological revolution and rapid industrial transformation, the continuous evolution of the new crown pneumonia epidemic, and the accelerated restructuring of industrial and supply chains, maintains its status as a major industrial province and walks out of “steady growth” “The road is particularly difficult, and the role of industry as the “ballast stone” of Jiangsu’s economy continues to be highlighted.

In the “14th Five-Year Plan” and the 2035 long-term goal outline, the national plan clearly stated for the first time that “maintain the proportion of manufacturing industry basically stable”, and Jiangsu is unique in including this item in the specific index system for the first time. Driven by the policy background, industrial robots, as an important subdivision track for the high-quality development of the manufacturing industry, have flourished and flourished in Jiangsu in recent years.

Striving to be the first, Jiangsu industrial robots are at the right time

In recent years, Jiangsu’s industrial robot industry has developed rapidly. According to the database of the Prospective Industry Research Institute, as of December 5, 2022, there were 28,866 industrial robot companies in Jiangsu Province, ranking first in the country; industrial robot companies were newly established in the past two years. There are 16,322 enterprises, accounting for 56.54%; there are 8,247 enterprises established within one year, accounting for 28.57%.

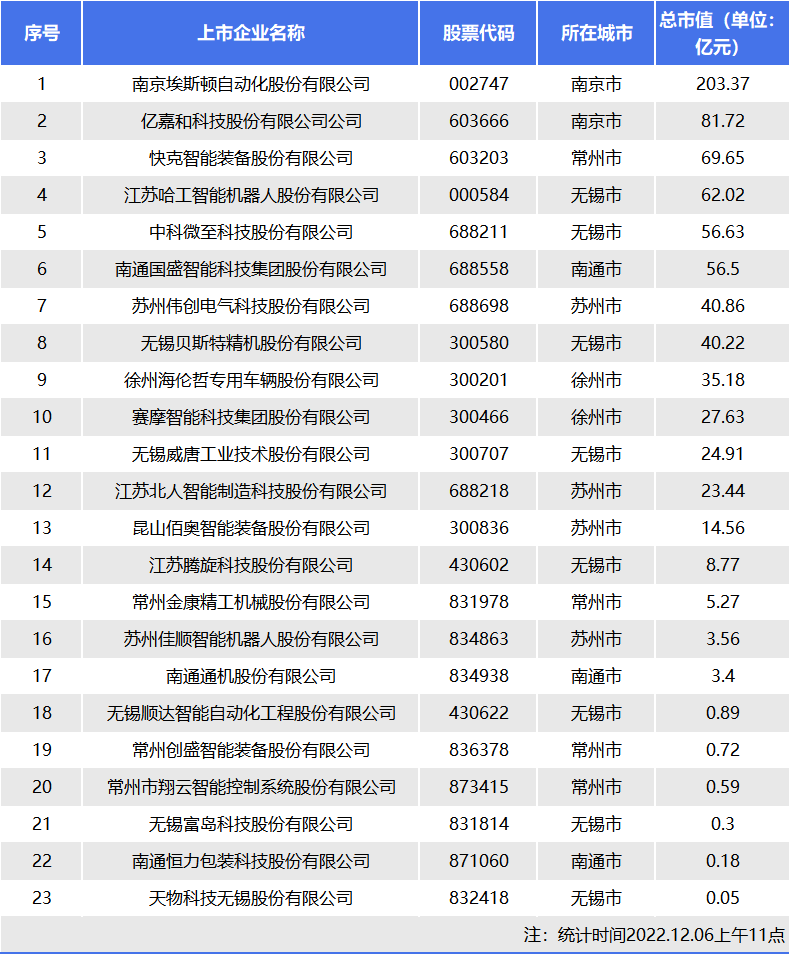

Jiangsu Province not only has a large number of industrial robot companies, but now a number of high-quality industrial robot companies in Jiangsu are also rapidly emerging. According to statistics, there are currently 47 listed industrial robot companies in Jiangsu Province, such as Nanjing Estun automation Co., Ltd., Nanjing Panda electronic Equipment Co., Ltd., Kunshan Baiao Intelligent Equipment Co., Ltd., Jiangsu Changhong Intelligent Equipment Group Co., Ltd. and other enterprises have also obtained national standard certification enterprises, which meet the “Industrial Robot Industry Standard Conditions”.

Listed companies and market value of some industrial robots in Jiangsu Province

Policy first, the rapid rise stems from the layout of the article

The industrial robot industry in Jiangsu Province is developed, mainly due to two factors:

On the one hand, the industrial economy of Jiangsu Province has developed rapidly over the past 70 years since the founding of New China, from 760 million yuan in total industrial added value in 1952 to 4.46 trillion yuan in 2021. Especially since the reform and opening up, Jiangsu’s industrial economy has ranked among the top in the country, and its industrial economy has always been among the top three in the country.

On the other hand, since 2000, the high-tech industry represented by the electronics industry has risen rapidly. In 2003, the electronics industry became the first pillar industry in Jiangsu, with a strong momentum of development. Other high-tech industries, such as pharmaceutical manufacturing enterprises, aerospace vehicle manufacturing enterprises, and medical instrument and instrument manufacturing industries, have shown a rapid growth momentum, and Jiangsu’s high-tech industrial system has initially formed.

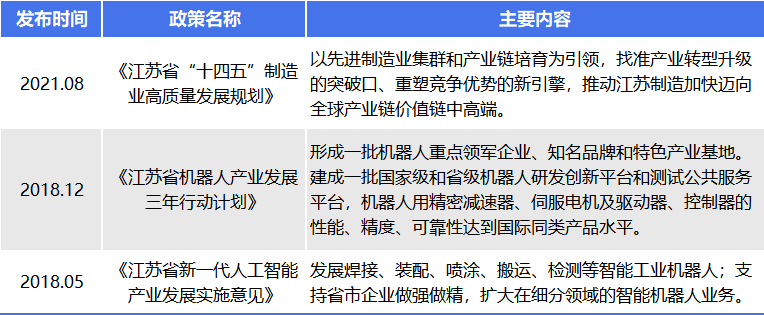

At the same time, the development of emerging industries is also inseparable from the support and support of favorable policies. Since 2018, Jiangsu Province has begun to make frequent efforts in the robot industry policy:

In May 2018, the “Implementation Opinions on the Development of a New Generation of artificial intelligence Industry in Jiangsu Province” was released, proposing the development of intelligent industrial robots such as welding, assembly, spraying, handling, and testing; supporting enterprises in Jiangsu Province and cities to become stronger and more refined, and to expand their presence in subdivided fields smart robot business.

In December 2018, the “Three-year Action Plan for the Development of the Robot Industry in Jiangsu Province (2018-2020)” was issued. It is estimated that the output value of the robot industry in the province will reach 100 billion yuan in 2020, with an average annual growth rate of more than 35%. The output will reach 10,000 units, forming a group of key robot leading companies, well-known brands and the development goals of characteristic industrial bases.

In August 2021, the “Jiangsu Province “14th Five-Year” Manufacturing High-Quality Development Plan” was issued, proposing to guide the cultivation of advanced manufacturing clusters and industrial chains, identify breakthroughs in industrial transformation and upgrading, and reshape the new engine of competitive advantage , to promote Jiangsu manufacturing to accelerate towards the middle and high end of the global industrial chain value chain.

Jiangsu Provincial Industrial Robot Industry Relevant Policies

In addition, in recent years, cities in Jiangsu have successively issued relevant development policies for the industrial robot industry according to their own industrial positioning, supporting the rapid growth of local industrial robot companies and forming a cluster effect.

Relevant policies of Jiangsu Province’s departmental and urban-level industrial robot industry

Cluster effect, industrial robots overflow the Yangtze River Delta

Jiangsu Province has a good industrial foundation, and the robot manufacturing integration and application market started earlier, and it was the first in the country to issue the “Guiding Opinions on Accelerating the Cultivation of Advanced Manufacturing Clusters” and “Jiangsu Province’s “14th Five-Year” Manufacturing High-Quality Development Plan” The development direction of 16 advanced manufacturing clusters was clearly proposed in the “Jiangsu Province “Industrial Strong Chain” Three-Year Action Plan” clearly defined the cluster industrial chain cultivation project, and the province’s efforts were used to create a group of “industrial chains that cannot be dismantled, moved, “Unbreakable” industrial aircraft carrier.

Today, industrial robot industry clusters represented by Nanjing, Suzhou, Wuxi, and Xuzhou have been formed, and they are at the forefront of the country in terms of robot industry chain construction, market demand, and innovation resource layout.

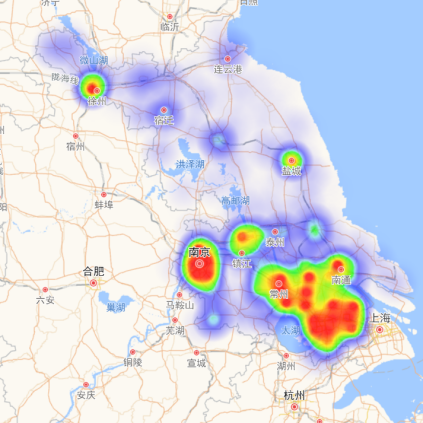

After 36 krypton analysis, it is found that due to the influence of regional industrial cluster effects and local development guidance policies, industrial robots in Jiangsu Province, whether it is the growth trend of enterprises in the past 5 years or the newly established industrial robot companies in the past 2 years, are mainly concentrated in southern Jiangsu: especially Nanjing, Suzhou, Changzhou, Wuxi and other places, Xuzhou is the “mainstay” of intelligent manufacturing in northern Jiangsu.

The heat map of the geographical distribution of newly established industrial robot companies in Jiangsu Province in the past two years as of 2022.12.6

Jiangsu continues to accelerate the industrial robot industry agglomeration, while continuing to extend the industrial chain.

Among them, the Nanjing robot industry chain has been extended to the field of artificial intelligence, and the industry’s competitive advantages and development potential have been further enhanced. Kunshan Robot Industrial Park is the first national incubator with the robot industry as the carrier in the country. Zhangjiagang and Haian Robot Industrial Parks are actively cultivating robot technology research and development platforms to create a robot cluster carrier. According to the incomplete statistics of 36 Krypton Jiangsu, there are currently 18 characteristic industrial robot cluster parks in Jiangsu Province, mainly concentrated in Nanjing, Xuzhou, Suzhou and other places, which is also consistent with the heat distribution of the above-mentioned enterprises.

Therefore, for some time to come, the manufacturing cluster effect will continue to overflow in Jiangsu Province, and the strength of the industrial robot industry with southern Jiangsu as the main core will drive the transformation and upgrading of the manufacturing industry in the Yangtze River Delta region.

Jiangsu Provincial Special Industrial Robot Concentration Park

Industrial application, explore more future imagination space

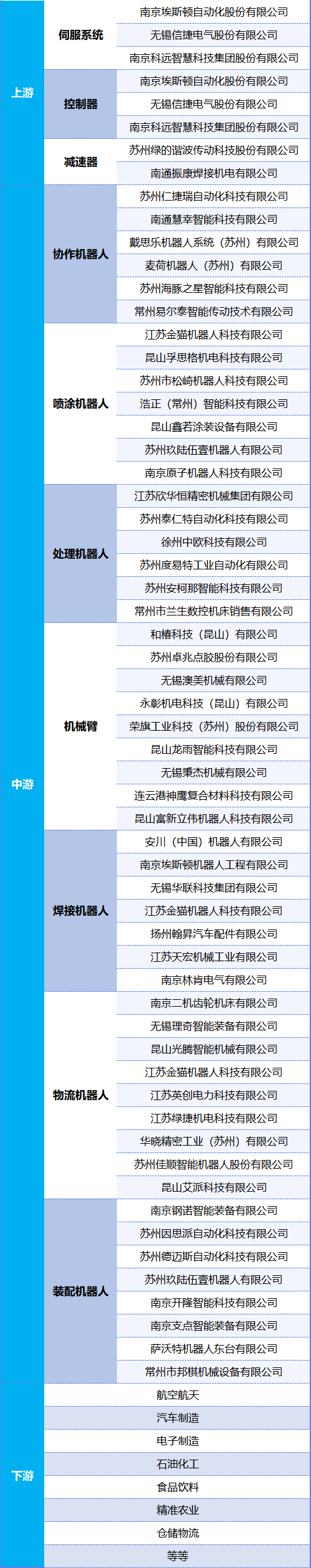

After more than 30 years of development, the industrial robot industry has formed a complete industrial chain. In the upstream of the industrial robot industry chain, it includes the three core components of the controller, servo system and reducer. These three components are the core technology of industrial robots. Jiangsu enterprises Estun, Keyuan Wisdom, Xinjie Electric , Green Harmony, Nantong Zhenkang and other enterprises strive to be the first, and deeply cultivate domestic technology reserves in the upstream of the industry.

Nanjing Estun Automation Co., Ltd. was established in 1993 and was successfully listed on the Shenzhen Stock Exchange SME Board in March 2015. Its business has covered the entire industrial chain from automation core components and motion control systems, industrial robots to robot integration applications, and has built an all-round competitive advantage from technology, cost to service.

Suzhou Green Harmonic Transmission Technology Co., Ltd. was established in 2011 and was successfully listed on the Science and Technology Innovation Board in August 2020. Green Harmonic is a core component manufacturer in the field of precision transmission, mainly engaged in the research and development, production and sales of harmonic reducers. Harmonic reducers are one of the core components of robots, and they need to work in combination with motors. Movement Joints”. When a robot is added to the reducer, it can complete fine movements such as turning, waving, and pinching. Green’s harmonic products are widely used in high-end manufacturing fields such as industrial robots, service robots, CNC machine tools, aerospace, medical equipment, semiconductor production equipment, and new energy equipment. Breaking through monopoly and other aspects are the first in China, and it is a well-deserved leader in the subdivision of domestic harmonic reducers.

Nanjing Keyuan Smart Technology Group Co., Ltd. was founded in 1993 and listed on the Shenzhen Stock Exchange in March 2010. Keyuan Wisdom has long been committed to the localization breakthrough of key technologies in the field of industrial automation, effectively improving the technical level and market competitiveness of domestic electro-hydraulic actuators.

Wuxi Xinjie Electric Co., Ltd. (XINJE) is a well-known domestic enterprise focusing on the R&D and application of industrial automation products. It has core products such as programmable logic controller (PLC), human-machine interface (HMI), servo control system, variable frequency drive, etc.; cutting-edge products such as intelligent machine vision system, manipulator based on teaching, robot, etc. and information network A more comprehensive set of automation equipment, closely serving end customers, and customizing more competitive sub-industry solutions for equipment manufacturing enterprises.

In the middle reaches of the industrial robot industry chain is the manufacture of robot bodies. The four major families of FANUC, ABB, KUKA, and Yaskawa have obvious advantages, accounting for 40% of the global industrial robot market share. High-speed catch-up phase.

But now in many fields such as collaborative robots, spraying robots, processing robots, Robotic arms, welding robots, logistics robots, assembly robots, etc., more and more Jiangsu enterprises are striving to compete at the forefront of industrial technology, and continue to iterate new products. In Jiangsu, we can not only feel the rapid development of the industrial robot industry, but also see that more and more industrial robots that are more suitable for manufacturing, have a higher degree of freedom, are softer and are more flexible are appearing in various Among the application scenarios of Jiangsu Zhizao.

For example, Jiangsu Beiren Intelligent Manufacturing Technology Co., Ltd. has formed a complete technical system with welding robot system integration as the core and other industrial robot system integration as auxiliary. Application, Manufacturing Execution System (MES) development, product standardization and other research fields have rich technical reserves, and can continuously provide downstream customers with new products and services, and a variety of innovative products have been fully recognized by downstream customers.

Elite Robot Co., Ltd. has achieved independent research and development from the underlying operating system, to embedded hardware and software, process packages and top computing power, to the modular joint technology of collaborative robots, except for the reducer. The EC series collaborative robot products currently on sale by ELITE have accumulated a good reputation in the industry for their stable operation, smooth dragging, complete functions and high cost performance. And successfully introduced head customer collaborative robot projects including auto parts, 3C electronics, metal processing, home appliances, electric power, and new retail.

The products of the soft touch robot can handle a piece of soot with ease, and even volleying Thomas will not hurt him at all. Since its entry into the market in 2017, the flexible gripper products of Soft Touch Robot have provided a more optimal flexible gripping solution for users to solve the problem of automatic gripping. It has the characteristics of high efficiency, low cost, easy control and ability to adapt to complex environments. It can better solve the manufacturing difficulties of flexible, special-shaped, fragile, complex environments and other scenarios in the industrial field.

The Qingzhan Soft Robot of the Qingzhan Artificial Intelligence Research Institute can rely on the autonomous navigation mode, which is small, flexible, high-precision, and fast. It also integrates powerful functions such as autonomous route planning and 360° rotation. Through the equipped rotary jacking system, the shelves where the goods are located can be moved from the warehouse storage area to the designated location, which greatly improves the processing efficiency.

Aiming at the track of “refinement of force control”, Yinglian Technology has independently developed the Active Compliant Force Control System (ACF) and its supporting force control grinding equipment, which are the key components to realize the robot’s sensitive contact force control on “curved surfaces”. The independent control system does not depend on any robot, it can be adapted to any kind of grinding tools, and the response speed is fast. It has the system advantages of increasing efficiency, reducing costs and improving quality.

Stial, which focuses on “active flexible grinding robot”, has the robot brain (bottom control system), AI sensory nervous system (flexible force control, tactile vision, intelligent tracking compensation), body design, and grinding process solutions. Complete independent closed-loop core technology, perfect layout in terms of hardware, software, algorithm, and process, with dozens of national patents, its “active flexible grinding robot”, which simulates the hand feeling design of a grinding craftsman, has served global customers for more than 15 years, Take the lead in realizing batch polishing of products in different scenarios in the world, and has accumulated the world’s leading patented technology and industry data.

As for the downstream application of industrial robots – system integration applications, the current application of industrial robots in Jiangsu Province is mainly concentrated in the automobile manufacturing and 3C electronics industries. Market segments such as lithium batteries are also growing rapidly.

In 2021, the number of industrial robot applications in Jiangsu Province will increase significantly, and the growth rate of industry development will be obvious. In the first half of the year, the output of industrial robots in the province will reach 28,199 units (sets), a year-on-year increase of 92.76%. Information from the Jiangsu Provincial Bureau of Statistics also shows that in 2020, the province’s industrial robot operating income will be 6.284 billion yuan, accounting for 11.82% of the national proportion; the output of industrial robots will be 36,726 units (sets), accounting for 15.49% of the national proportion.

Innovative industrial robot enterprise in Jiangsu Province

epilogue

As mentioned above, Jiangsu’s industrial robots are showing huge room for development and broad application prospects in various emerging industries. In fact, the industrial robot industry not only interprets strong scientific and technological aesthetics, but also explores more realistic scenarios for us. With more room for imagination in the future, 36Kr Jiangsu will continue to follow the industry development at the forefront, discover more high-quality local projects, and empower more cutting-edge enterprises.

The Links: 3HAC14178-1 3HAC021663-006

Pre: Booming Industry Robot in China Next: Supcon Professional Services Plans fo...