Smart manufacturing + standardization | Schaeffler promotes the implementation of the 2022 national smart manufacturing standard application pilot project

On October 26, Schaeffler’s 2022 National Intelligent Manufacturing Standard Application Pilot Promotion Ceremony was held at Schaeffler’s new base in Taicang.

Mr. Uwe Wagner, Chief Technology Officer of Schaeffler Group, and Mr. Andreas Schick, Chief Operating Officer, witnessed the ceremony online. Dr. Zhang Yilin, CEO of Schaeffler Greater China, Dr. Liu Yong, Chief Technology Officer, Dr. Chen Xiangbin, President of Automotive Technology Division, and Mr. Xi Peng, head of Taicang Manufacturing Base, jointly launched the project with external guests.

Wang Yan, deputy director of the Suzhou market Supervision Administration, Mao Yaping, member of the Standing Committee of the Taicang Municipal Committee and Secretary of the Party Working Committee of the High-tech Zone, Zhang Zhan, deputy mayor of Taicang, Yang Weidong, director of the Taicang Market Supervision Administration, Taicang High-tech Zone Management Committee, The letter bureau and relevant departments, as well as representatives from associations, media and neighboring enterprises of the Taicang base were invited to participate in the ceremony.

The 2022 Smart Manufacturing Standards Application Pilot Project was jointly launched by the State Administration for Market Regulation (Standardization Committee) and the Ministry of Industry and Information Technology of the People’s Republic of China. A total of 59 projects across the country were selected. The “Smart Factory Standard Application Pilot Program for Core Components of New Energy Vehicles” declared by Schaeffler has become the only selected project in Suzhou and the only smart workshop/factory construction project for new energy vehicle components in Jiangsu Province.

“Schaeffler is a global enterprise with high international standards. In the current period of accelerated transformation, we need innovation and standardization even more. Facing the future, we will continue to lead innovation-driven development with excellent technology and capabilities!”

——Chief Technology Officer of Schaeffler Group

Uwe Wagner

To build a smart factory

The “standard group” in the field of construction actively assists

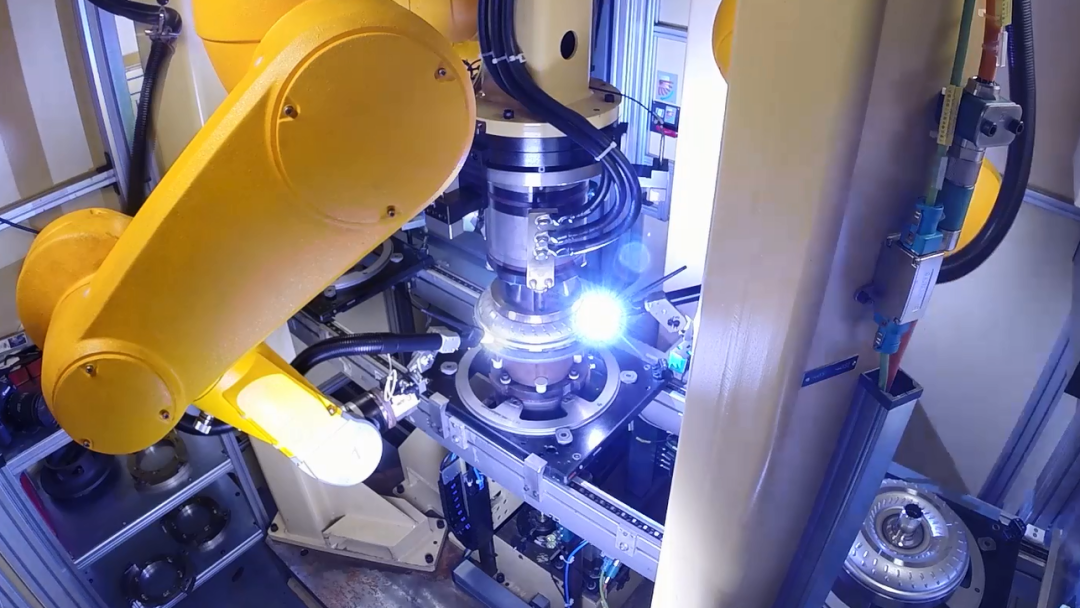

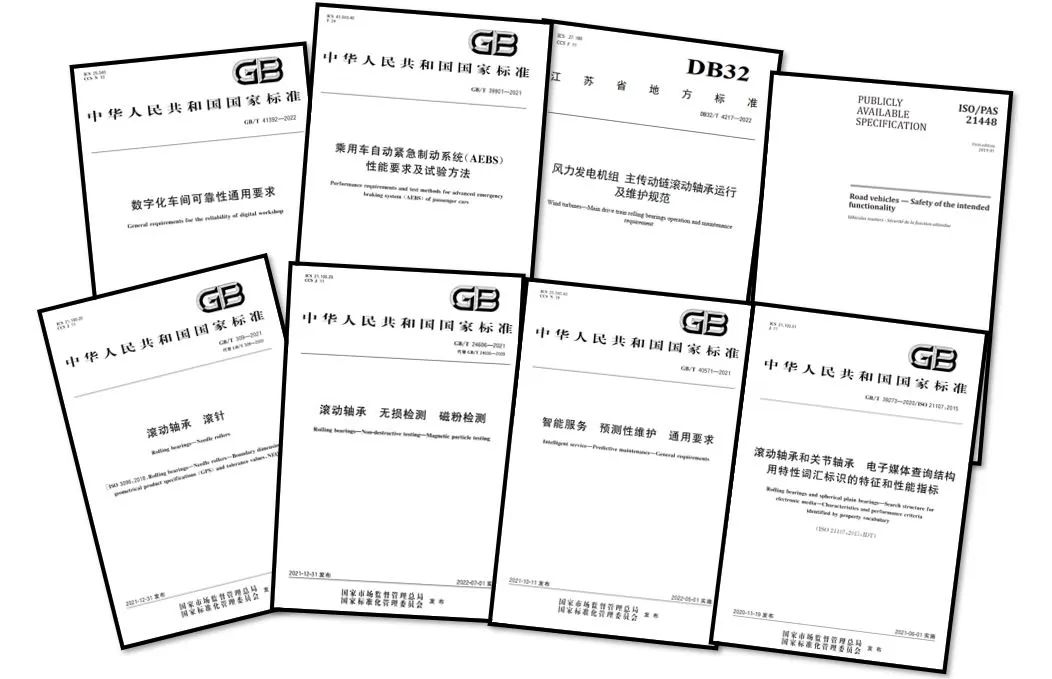

Relying on the construction of smart factories in Schaeffler’s Taicang new base, Schaeffler will focus on the integration and interconnection of smart equipment and information systems in new energy auto parts production lines, workshops and factories in accordance with the requirements of the “Smart Manufacturing Standard Application Pilot Implementation Plan” In terms of interoperability and security, actively promote the application and implementation of a series of national standards such as “General Requirements for Digital Workshop Reliability” (GB/T 41392-2022).

The implementation period of the standard application pilot project is two years, and it is planned to be carried out in three stages, including improving the application materials of the “standard group”; forming project proposals, implementation guidelines or solutions; actively promoting the pilot experience, etc., to promote the construction of China’s smart factory The “standard group” of advanced countries in the construction field actively assisted.

Deeply plowing China’s standardization construction

Accelerate the exploration of “smart manufacturing + standardization”

Over the years, Schaeffler has focused on business, complied with the development trend of the industry, actively cooperated with national and local standardization organizations, participated in and promoted the construction of industry standardization, and achieved fruitful results.

Up to now, Schaeffler has become a member unit of SAC/TC124 (National Industrial Process Measurement Control and automation Standardization Technical Committee), SAC/TC98 member unit (National Rolling Bearing Standardization Technical Committee), SAC/TC159 member unit (National Automation System and Integration Standardization Technical Committee) and SAC/TC114 (National Automobile Standardization Technical Committee) and other organizational members have taken the lead and participated in the formulation of more than 20 international standards, national standards, industry standards, local standards and group standards, including “Digital Workshop Reliability General Requirements” (GB/T 41392-2022) and many other national intelligent manufacturing core standards.

“As a global technology-based company, Schaeffler uses innovative standardization exploration to help the industry develop and deeply cultivate the Chinese market. Schaeffler will further accelerate the innovative practice of ‘smart manufacturing + standardization’, and contribute to the digital transformation of the domestic manufacturing industry, Actively contribute to the development of standardization.”

—— Chief Technology Officer of Schaeffler Greater China

Dr. Yong Liu

The Links: TB840/3BSE021456R1 3BSE037760R1 IGBT

Pre: Go all out to support the development... Next: Have fun with the ABB Robotics Online...