From 1 to N, this secret weapon you must have!

A few years ago, even if you had only two AMRs in your factory, you could be considered an advancedDigitizingFactories, but these days warehouses, factories and other facilities are deploying AMR fleets on a large scale, it is not new for a manufacturer to have a fleet of AMRs, but if you still think that AMR is just a kind of logistics to move goods from point A to point B Transporter, then we now have good news and bad news for you.

The bad news is that you have yet to discover the full capabilities of the K-MR Picture S system.

The good news is that your relationship with KUKA AMR has only just begun.

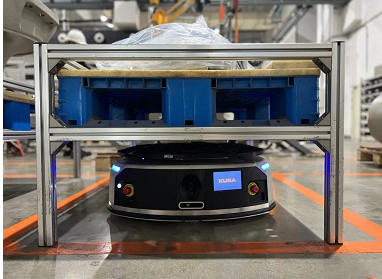

With the characteristics of intelligence, efficiency, flexibility, convenience, safety and stability, AMR has been widely used in e-commerce warehousing, 3C electronics, semiconductors, automobiles and parts, high-end equipment manufacturing, etc., but only relying on the AMR body is far from being competent. Enterprises deploy AMR on a large scale and maximize the advantages of intelligent upgrades. Therefore, an excellent software platform is particularly important.

KUKA AMR

![]()

High-quality software can enhance the intelligence and flexibility of AMR, making it easier for users to issue commands more quickly androbotThe operation is safer, more stable and more accurate; secondly, as more and more enterprises need hundreds of AMR clusters to operate, this puts forward higher requirements for the algorithm and computing power of the AMR commander cluster scheduling system.

The K-MR picture S (KUKA Mobile Robot Expert System) independently developed by KUKA AMR is based on a variety of complex AI scheduling algorithms to help companies deploy AMRs fleets quickly and efficiently, from 0 to 1 to N In addition to rapid deployment, it also has the ability of flexible process orchestration and full coverage of peripheral docking, and can manage several AMRs to operate in the same field at the same time, ensuring 7×24 hours of uninterrupted operation.

In addition, the K-MR image S system will help enterprises to realize the whole process and group intelligence of various types of mobile Robots in the factory, task execution and efficient collaboration, breaking system barriers and supporting various Industrial manufacturing scenarios, so that It is more widely adapted to customers’ internal logistics planning and management operations, and helps enterprises to build intelligent and digital smart factories.

As the saying goes, the lower-level foundation determines the upper-level building, and the same is true in the AMR software platform. The underlying logic determines the upper limit of business processing. Only with a set of complete and powerful underlying algorithm logic and massive computing capabilities, AMR fleets can realize the functions of path planning, driving strategy, task scheduling, vehicle scheduling and proximity principle in the follow-up work to meet the needs of the scene. .

in K-MReIn the S system, KUKA AMR uses the Java web application of the Spring boot framework to write the underlying logic. Based on the three major modules implemented by JAVA web, K-RCS, K-WCS, and K-ECS can seamlessly connect to the upper-layer system, data information acquisition, task process scheduling, multi-robot scheduling coordination, external equipment docking scheduling and other functions to realize the factory automation, intelligence and digitization of manufacturing.

K-MR image S system software platform login interface

At this time, you will ask, why not the simple and easy-to-use Python or the common language C++/C# in manufacturing? In reality, not every business can choose a programming language to use based solely on its technical merits and suitability for a particular problem.

In addition to being not much different from traditional web programs, JAVA itself has many years of technical accumulation. It is true that it does not have the convenience and simplicity of a new language, but the underlying scalability and future development of the JAVA language All of them provide the basis for the future development and possibility of the K-MR image S system. In other words, we are not only optimizing our control systems, but also the productivity of our developers.

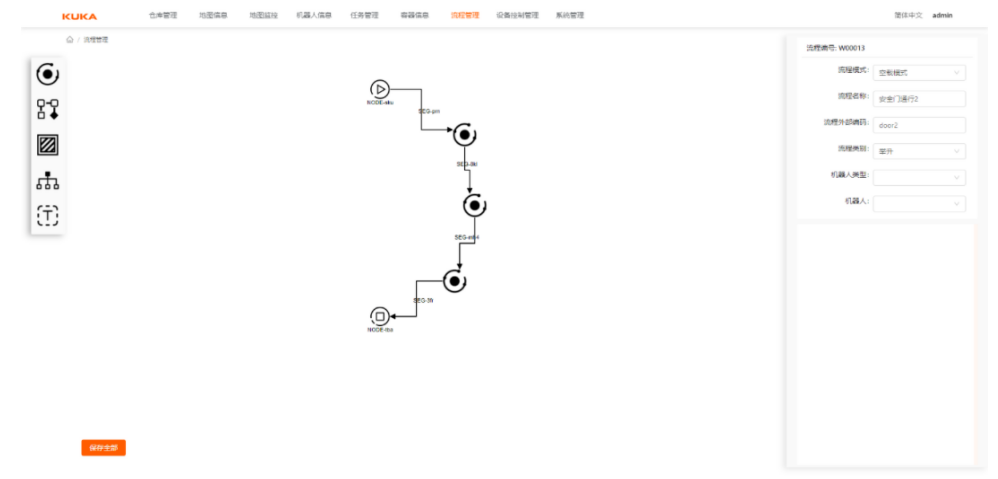

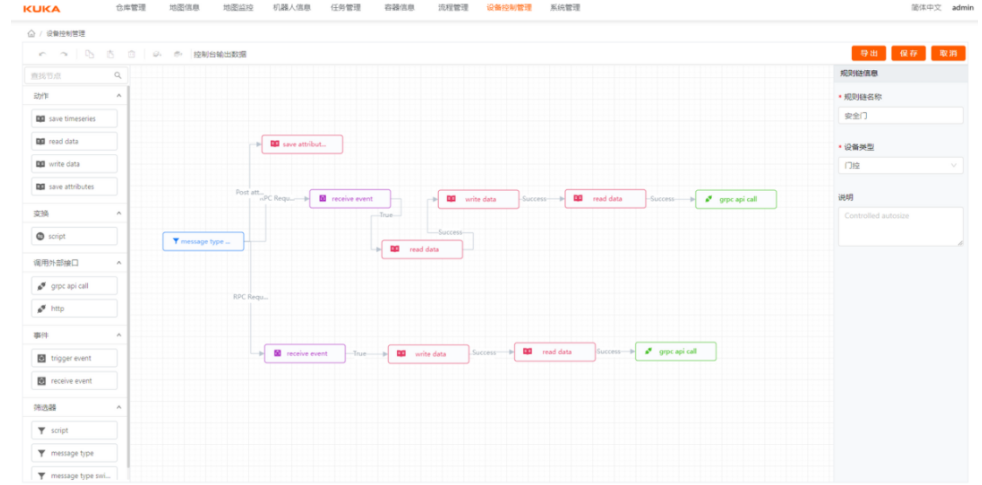

K-WCS process control system interface

Different from traditional B-end web systems, K-MR in the mobile Robot Industry

The S system not only needs to consider the basic characteristics of B-side products such as interaction and functional logic in the design, but also assumes more responsibility for connecting more hardware products. With the structural upgrading of consumption, individualized and customized consumption demands have become increasingly prominent, and there are more and more demands for diversified production, small batches, customization, and rapid iteration, which requires production lines to change from a fixed mode to a flexible and variable one. Pattern evolution.

KUKA AMR needs a more flexible and flexible production model for the current manufacturing industry, and needs to meet the needs of third-party equipment assistance, third-party equipment communication protocol docking, etc. The “flexible and flexible” feature really comes into play, which is also the real feature and capability of our K-MR image S system throughout the entire underlying structure and system layer.

Of course, the technology related to logistics and warehousing equipment needs to be continuously innovated in both hardware and software to launch reliable technologies and products. But in fact, the homogeneity of software systems, scheduling systems and business systems in the current software market is relatively serious. Therefore, how to innovate, achieve differentiation, break the market situation, and truly empower customers is particularly important.

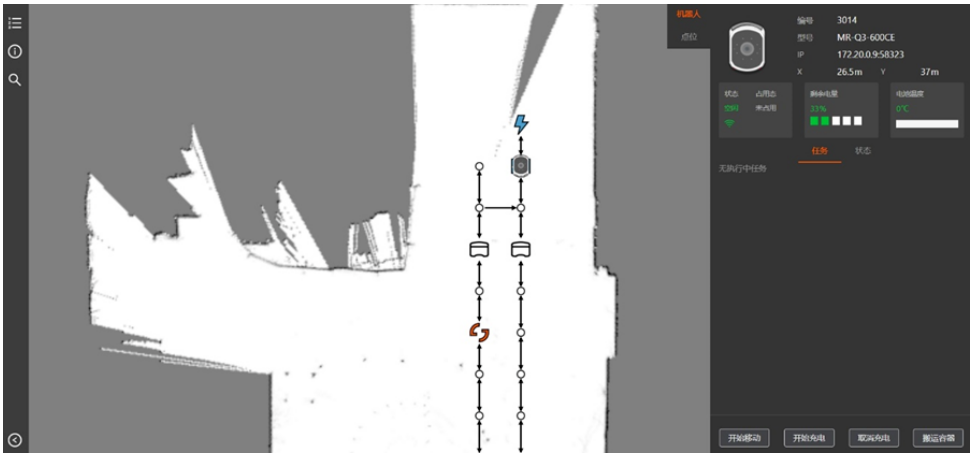

K-RCS robot scheduling system interface

However, this is not a big problem for KUKA AMR.

Unlike most software systems, K-MR

From the very beginning, the S system has never thought of “closing the door”. From AMR coding products to AMR body hardware to AMR software system, KUKA AMR fully integrates openness into the design. Currently, K-MR

The S system can easily access various communication software, analysis software, and safety detection software, and enables AMR to be tightly integrated with the existing EPR and WMS systems of the customer’s factory.

Do you think that’s all?

of course not! The openness is not limited to the software itself. In addition to the compatibility of the system, KUKA AMR is also compatible with third-party robots. Yes, that is, if you have deployed a non-KUKA AMR, then you do not need to adapt to K-MR images. S system and replace a batch of AMRs. At the same time, KUKA AMR also supports interface customization, or opening the interface for cooperative development by enterprises.

K-ECS equipment control system interface

In addition, KUKA AMR pays special attention to system design, such as low-code development, functional modularity, and logic graphics. Users can help enterprises to complete business development by simply “pulling and dragging”, and also supports automatic database generation, process business processing, and graphic process design. In other words, an application system can be built with a few mouse clicks. No need for a lot of hands-on coding steps.

However, K-MReThe S system is not a panacea. Even with a good system, there are still many problems in the process of using the system in enterprises.

For example, the enterprise does not have a clear understanding of its own business, which makes the software system unable to fit the enterprise business, unable to provide enough value to the enterprise, and difficult to solve the follow-up problems faced by the enterprise after the system deployment is completed.Therefore, if there are no operators in the enterprise who can understand the system well to carry out the operation and maintenance management of the system, this will also become a problem for the enterprise.digital transformationOne of the puzzles of upgrading.

However, for KUKA AMR, this is still not a big problem.

In the early stage, KUKA AMR will carry out “1V1 service”, “tailor-made” for customers, and create exclusive services; in the later stage, KUKA AMR will also provide “accompanying running” services to help customers digest and understand the operating background and principles, and help customers establish initial concepts and concepts after deploying AMR. Operations management.

As for the specific content of the service, let me sell it first, and let’s talk about it in the next issue~ (To be honest, there is indeed too much content, and I can’t explain it in a few words, so I have to think about it in the long run…)

If you are looking forward to it, add a follow, give a thumbs up, we will see you in the next issue!

The Links: 3BSE045584R1 JANCD-NBB31B

Pre: The first share of “Smart Facto... Next: Zhangye Zhizao helps the national ant...