Bottle Neck of China Industry Robot

The report released by the CCID Research Institute of the Ministry of Industry and Information Technology also pointed out that under the pressure of policy support and labor costs, China’s robot industry is expected to grow at an average annual growth rate of 23% to 36% in the ten years from 2012 to 2022, with a potential market size of 100 billion meta level.

Under the background that China’s manufacturing industry is transforming to high-end, undertaking international advanced manufacturing, and participating in international division of labor, industrial robots are also expected to become an important force to promote transformation.

How will industrial robots change China? A few days ago, “Wangdongfang Weekly” interviewed Cai Hegao, an academician of the Chinese Academy of Engineering.

As the honorary director of the Harbin Institute of Technology Robot Research Institute, Cai Hegao is one of the pioneers of domestic industrial robots. In 1985, he successfully developed China’s first arc welding robot. The project was compared to Sputnik when it was exhibited at the China Military Museum in Beijing.

In this interview, Cai Hegao once again emphasized that only by solving the development problem of industrial robots can China realize the transformation from a manufacturing power to a manufacturing power.

100 million people do the work of 10 million people

“Wangdongfang Weekly”: What is the concept of industrial robots? What does it do?

Cai Hegao: In the 1960s, the United States first successfully developed the first industrial robot. At that time, the American industry was developing rapidly, but the labor force was insufficient and labor costs continued to rise. They considered researching a machine that could replace humans in various operations in factories, such as welding, painting, handling, assembly… This kind of robot began to look like a human arm, with a big arm, a small arm, and a human arm. Wrists, hands, can do various actions according to programming. You can weld with a welding torch in your hand, spray paint with a spray gun, and carry it with claws. At that time, the American automobile industry was developing rapidly, and robots were first used in automobiles.

Japan also faced the problem of labor shortage and high labor cost after the war, and soon introduced this technology. The government issued support policies, and the industrial robot industry developed quickly. For robot manufacturing factories, the government provides subsidies to reduce the risk of manufacturing robots, thus stimulating the enthusiasm of factories. Users will also receive government subsidies for purchasing and using robots, and the more they use, the more subsidies they will get. Today, Japan has become the country that produces and uses the most industrial robots in the world.

Japan called 1980 “the first year of robots”, and they basically achieved industrialization and promotion and application in this year.

Industrial robots were also developed later in Europe, such as Germany and Sweden developed rapidly. Sweden’s ABB company and Germany’s KUKA company all developed under such a historical background.

China began to include robots in the national plan in the early 1980s, and later included in the “863 Program” and the Natural Science Foundation of China. It has been more than 30 years since then, and we have been able to manufacture industrial robots, but the industry has not yet developed and grown, and the scale is also very small. It can only be said that it is still in its infancy. At present, there are no enterprises in China that produce robots on a large scale like KUKA, ABB, and Yaskawa. But in the past 30 years, we have also made certain achievements in industrial robots.

“Wangdongfang Weekly”: To what extent is the application of industrial robots in western countries?

Cai Hegao: Like Japan, the number of robots corresponding to every 10,000 workers is more than 300, while China has less than 20. From this perspective, China has a huge potential market. Because China is a big manufacturing country, in 2010 our total manufacturing volume has surpassed that of the United States. But we did it with 100 million workers, and 10 million workers in the United States. This figure shows that our production efficiency is less than one-tenth of that of the United States, and our production methods are still very backward.

In 2010, I went to some coastal enterprises to see that although the products could be exported and the output was large, they were all manual and labor-intensive. When I went to the workshop, many people were welding, assembling and making by hand.

In the past few years, China has also encountered problems that Western countries and developed countries have encountered in the past-labor shortage and high labor costs. China doesn’t have so much cheap labor, how will it develop in the future? China is facing industrial transformation and upgrading, and will change from a big manufacturing country to a manufacturing powerhouse. Therefore, there has been a period of high demand for industrial robots.

Some people say that China’s industrial robot market will become the world’s largest demand market, because China’s manufacturing industry is very large, and it needs millions of industrial robots to upgrade to the level of automation like the United States, Japan, and Germany.

Because of this, several large foreign robot companies, such as KUKA, ABB, and Yaskawa, have come to China to build factories in Shanghai, Chengdu, Shenyang, Beijing and other places. They have found that they must use cheap products to compete with China, so they use Chinese labor to produce locally and reduce long-distance transportation costs.

We cannot hand over China’s robot market to foreigners. We must develop our own industrial technology industry and use domestic robots with independent intellectual property rights to occupy the Chinese market. So now the state, local governments, and entrepreneurs are actively establishing the robot industry. From a national perspective, hundreds of such enterprises are in their infancy.

Key components must be imported from foreign countries.

“Wangdongfang Weekly”: What is the current output of industrial robots in China?

Cai Hegao: There are statistics in 2013, but the figures are not particularly accurate: the total number of newly sold robots in China is about 110,000 to 120,000 units. Among them, the robots made in China may account for one-tenth, and 90% are imported – Kuka, ABB, and Yaskawa. When I went to Shanghai Automobile Works, First Automobile Factory, Second Automobile Factory, BAIC Motor, and Nanjing Automobile Factory, I found that robots are used a lot, and most of them are foreign.

If China wants to reach the production efficiency of the United States, it needs to equip more than 3 million industrial robots, and there is still a gap of several million units. These major foreign manufacturers cannot produce so many, so there is a lot of room for the development of China’s industrial robot industry.

“Wangdongfang Weekly”: Do domestic industrial robots face challenges in terms of price, performance, and technology?

Cai Hegao: This is really a serious problem. China can make robots, and they can be used after they are made, but to build an industrial robot with 6 degrees of freedom, 6 servo motors are needed. Servo motors cannot be made in China and have to be imported. In addition, each joint has a precision reducer, which also has to be imported from Japan. Imported motors and reducers are expensive.

Although our labor force is cheap, it is very difficult for domestic enterprises to reduce the cost of robot manufacturing—the key components must be imported from foreign countries. This factor restricts the development of our industrial robot industry.

China is also trying to make its own servo motors and reducers, but it has not been fully resolved. Our goal is that the performance can at least reach the level of foreign countries, and the price is one-third of foreign countries.

“Wangdongfang Weekly”: How do you see the current development of industrial robots?

Cai Hegao: There are three generations of industrial robots. The first-generation robot is a teaching-reproduction type. Program it and teach it what to do. It will faithfully follow the program, and it will not lose shape after a thousand or ten thousand times. But this kind of robot has no sensory system. If the external environment changes, it has no feeling, let alone thinking function, and cannot plan its own behavior. The most widely used foreign industrial robots are still the first generation of robots. It is the second-generation robot that has the function of perception, and the current application is not as common as the first-generation robot.

The second generation, that is, robots with perception functions, such as vision functions, can judge the position and direction of movement of parts, and can even put parts of different shapes such as circles, squares, and triangles into different boxes. Robots with perception functions have been applied in production, but there are still relatively few, and now 90% are the first generation.

The detection robot launched to Mars is intelligent and can make independent judgments and decide what to do. Fully autonomous robots have not yet appeared, and this robot belongs to the third generation of intelligent robots.

Industrial robots receive high-level attention.

“Wangdongfang Weekly”: Some people say that the application of industrial robots has brought about a high unemployment rate in the United States and other countries. What do you think of this statement?

Cai Hegao: The trend of the entire production development is to automate and mechanize production operations. In developed countries such as the United States, Japan, and Germany, although many of them have been automated by robots, there are still many labor operations that still rely on humans, such as construction, agriculture, and mining. The general trend is that physical labor is less and less, but mental work can be done.

For China, is it better to use people or robots? This does not mean that we can do whatever we want. This is closely related to the historical development, economic development, and productivity development of the entire country.

In the past, China had a large labor force and a large agricultural population, but China cannot always be in this state. Due to the improvement of economic conditions and the shrinking of the labor force, there is a new trend of replacing people with robots.

In this case, if we still go the old way, it will not work, we can only take the way of automation. This is too similar to the history of developed countries in the past, such as the United States, Japan, and Germany. China’s economy needs to be transformed and upgraded, and it is necessary to transform from a manufacturing power to a manufacturing power. This is an inevitable stage of historical development. If you want to go this way, you have to go, and if you don’t want to go, you have to go.

“Wangdongfang Weekly”: How long do you think it will take for China to realize the goal of automated production through industrial robots?

Cai Hegao: Some people say in 2025. In China, it is possible to realize the dream of manufacturing a powerful country, but it is very difficult. From top to bottom, from all levels of government to various enterprises, various scientific research and school departments, everyone must work together to solve this transformation and upgrade, and to achieve the goal of building a strong manufacturing country.

We also need to cultivate the high-tech talents needed by manufacturing powerful enterprises, the technical talents who can use, operate, and maintain industrial robots. The entire production technical team and talent team must be of high level.

Robots were mentioned in the report at the academician conference, and it was the first time in history that national leaders took robots as a specific issue. I was very excited after hearing this report. From the level of national leaders, it is so important that China’s industrial robots have hope.

Now the development momentum is very strong everywhere, the temperature is very high, a bit like mushrooms after rain. But who can make it in the end? It depends on who can make large-scale production. It must have a large output and a large number of users like KUKA, ABB, and Yaskawa. This is called success.

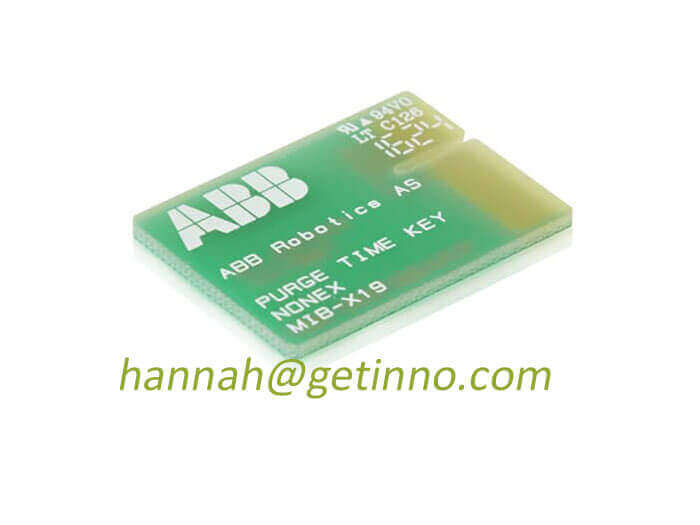

Links: SS832 3BSE013230R1

Pre: Nankai University’s new achieve... Next: Status Quo of Industry Robot