China Lag Behind Industry Robot?

For China, which ranks second in GDP in the world, this does sound a bit miserable. But what’s the problem?

By definition, a robot is a flexible machine with seven characteristics: mobility, individuality, intelligence, versatility, semi-mechanical and semi-human, automaticity, and slavery. The industrial robot is a kind of automatic control, programmable, multi-functional actuator with 3 or more programmable axes, which is applied to industrial automation.

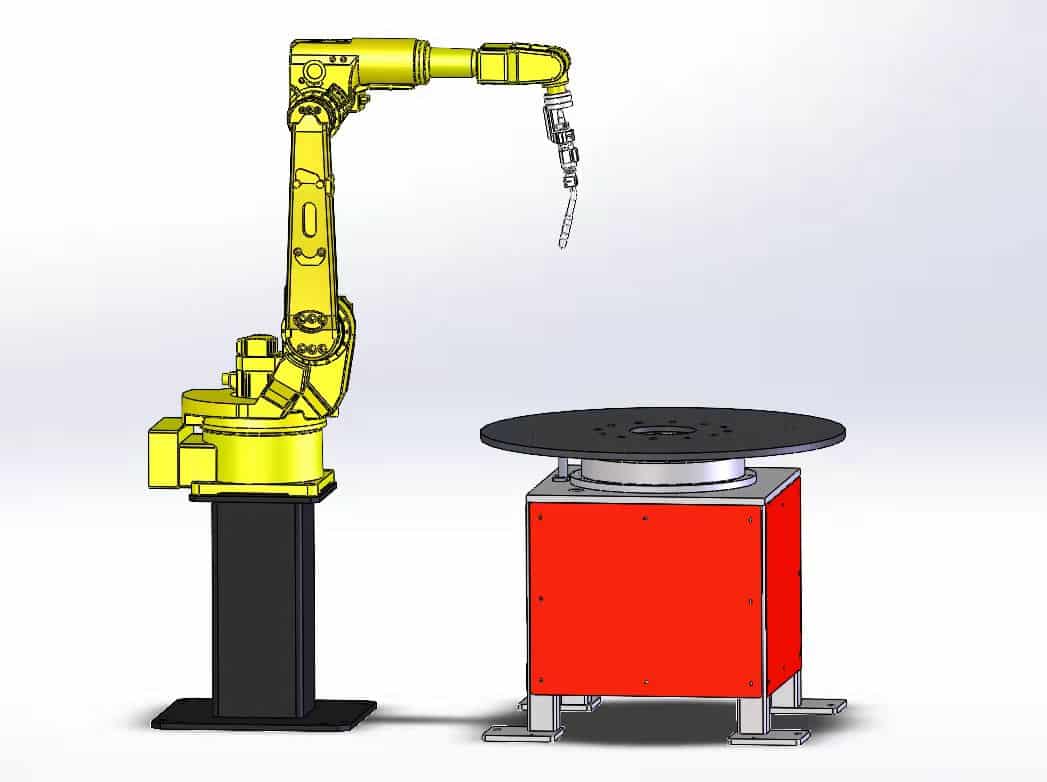

Simply put, the mechanical structure of the robot is composed of metal components connected to each other through several movable joints, some of which can rotate and some can be stretched. Because it is similar to a human arm, some people call the current industrial robot a mechanical arm.

A servo is installed on each joint, which is composed of a servo control computer, a servo system and drive components. Servo control is an automatic control method that takes the mechanical position or angle as the control object. After receiving the action instructions sent by the master controller, the servo drives the joints to complete the specified actions.

The controller calculates and generates the position, speed and acceleration designation of each moving part, and sends it to the servo to manipulate the center point of the robot gripper or robot tool to reach the target point along the given trajectory at a given speed.

Among these three components, the servo system consists of a precision measurement signal feedback system, a drive motor, a reducer and a servo computer system. The action of each joint must be powered by the drive motor, which is decelerated by the reducer and then output with increased torque. Industrial robot reducers require small size, light weight, large transmission ratio, high transmission efficiency, high motion accuracy, small hysteresis, low vibration, high rigidity and high reliability. And the RV reducer developed on the basis of cycloidal pinwheel transmission is the most important. The motor driven by the joint requires a large power-to-mass ratio and a large torque-to-inertia ratio, high starting torque, low inertia, and a wide and smooth speed regulation range.

In the cost of industrial robots, the highest proportion is the reducer, accounting for 33% to 38%, the drive and servo motor account for 20% to 25%, the controller accounts for 10% to 15%, and the mechanical structure of the robot accounts for the total cost. Only about 20%. Due to my country’s progress in the field of CNC machine tools in recent years, although high-precision servos still need to be imported, they can already produce low-end and mid-range servos. The biggest problem of my country’s robot industry is the reducer, especially the RV reducer, which is called the “Queen” of the robot in the industry. Our country started too late, and it is basically completely blank.

For high-precision robot reducers, Japan is in an absolute leading position. At present, 75% of the precision reducers in the global robot industry are occupied by Japanese companies. The key technology of the RV reducer is the cycloid drive, which was first invented by the Germans in 1926, and was later bought out by a Japanese company to continue research and development. According to many factors such as processing, load, working conditions, materials, etc., the Japanese company proposed a modification plan for the original standard cycloid tooth profile of the reducer gear, obtained many patents, and mass-produced it around 1986. The product performance is superior, and almost every Upgrade every 6 years.

The design of the RV reducer requires special software, and accurate tooth shape data cannot be obtained only through surveying and mapping. The processing precision of the parts is extremely high, and the processing is extremely difficult. Since it is impossible to simply “copycat”, the road to independent research and development of RV reducers is extremely difficult. So far, the Chinese have applied for only 26 RV reducer patents, only 13 valid patents, and only 2 invention patents, none of which belong to the core technology. Foreign applicants applied for 47 patents in China, of which 26 valid patents were all invention patents.

Links: 3HAC044075-001 6av2124-0gc13-0ax0

Pre: Prospect of Industry Robot Next: What will the future of industrial ma...