Rapoo intelligent equipment applies RFID technology to show the “wisdom” of warehousing and logistics

The traditional warehouse management method is to use manual record and inventory method, which is very inefficient, and it is easy to cause incorrect inventory management information, which affects the normal operation of enterprise warehousing. With the increasingly fierce competition among enterprises, all enterprises are working hard to save costs and improve work efficiency. Warehousing management occupies a core position in logistics management. To carry out system integration, a technology based on information management needs to be completely transformed. The use of RFID (Radio Frequency Identification) technology as the key technology in the warehouse management system can significantly improve the level of warehouse logistics management, enterprises can obtain a good return on investment, and can effectively avoid or reduce repeated investment in enterprise information upgrades in the future.

The application of RFID technology in Rapoo intelligent equipment promotes customer warehousing from the traditional model to the modern information model, so that business owners can see the information of materials in the warehouse at any time in the background, improve the efficiency of warehousing work, and maintain the lean operation of enterprise business. Relying on RFID technology to manage warehouse materials, installing card readers and labels on each shelf, and collaborating with other intelligent warehouse logistics software, can quickly understand all the material information in the warehouse in real time, effectively simplify the complex operation process of the warehouse, and improve enterprise information management. Efficiency and transparency.

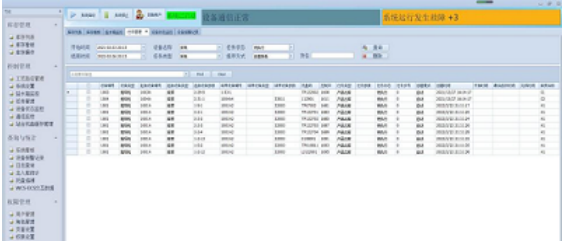

RFID is a non-contact automatic identification technology. The basic principle is to use the radio frequency signal and the non-contact transmission characteristics of spatial coupling to realize the automatic identification of the identified objects and exchange data. The data thus becomes traceable, and the client data interface supports functions such as viewing traceability information. The client is divided into two types of handheld client and PC client according to the software usage environment. The handheld client has functions such as receiving, picking, putting on shelves, and taking inventory, while the PC client has functions such as label initialization and delivery.

The warehousing logistics system is generally divided into four links: outbound, inbound, inventory management, and transportation. The use of RFID tags as the support of the logistics system can closely link all links. Implement whole-process control management for all aspects of warehousing, and realize RFID electronic label management for materials, which can achieve standardized operations in all aspects of receipt, delivery, etc., solve the phenomenon of outdated and lagging warehouse information, and promote warehousing and logistics links to be more efficient, accurate, and efficient. Safety.

To apply RFID technology in the warehouse logistics system for intelligent management, it is necessary to affix electronic labels to each material, and automate data collection through RFID readers to ensure the speed and accuracy of data input in all aspects of warehouse management, and to master inventory. Real-time data. Through scientific coding, the batch and shelf life of materials can be easily managed. The information entry of RFID tags can be divided into three steps:

①The label comprehensively describes the corresponding material information, including production process, production department, service period, safety level, etc. The information entered on the label will become a strong support for process traceability, and the relevant information of the material will be entered into the corresponding RFID label item;

② Sort out the database according to the material information. After completing the information entry, use the reader to confirm the information and check whether the information corresponding to the RFID tag is consistent with the material information;

③ Simultaneously carry out data entry, and Display the completion time and handler of the RFID tag information entry of each material. In order to ensure the uniqueness of RFID tags, the information of the same product can be sorted and encoded, which is convenient for quick inventory.

The warehousing requirements of warehousing materials are very strict. The warehousing of traditional warehousing and logistics systems strictly controls the three links of handling personnel, items, and records. The whole process requires a lot of manpower and time. In the warehousing system using RFID technology, the information exchange through RFID can be efficiently and accurately controlled. Through the reader at the entry channel, the RFID tag of the material can be identified, the corresponding material information can be found in the database, and automatically entered into the inventory management system, and the system will record and verify the entry information.

The inventory information system using RFID technology can directly guide the radio frequency terminal on the warehouse logistics equipment, select the target material level and find the best way to reach the location. Inventory information is updated as soon as the reader confirms that the material is in place. After the materials are put into storage, the storage list can be printed through the RFID system printer, and the responsible person can confirm it. After warehousing, it is also necessary to use the RFID system to conduct inventory inspection and management, conduct regular inspections of classified materials, and analyze changes in material inventory.

In the outbound RFID inventory management, the system will automatically determine the optimal pick-up path and pick-up area according to the outbound order requirements. The on-board terminal is used to remind the staff to load the goods. After scanning the RFID tags of the goods and the cargo space, the outgoing items are confirmed and the inventory is updated at the same time. When the material reaches the exit channel, the reader will automatically read the RFID tag of the material, and call up the corresponding information in the database, and compare it with the order information. If it is correct, it can be shipped out, and the inventory of the material will decrease accordingly Except; if there is an abnormality, the warehouse management system will Display a prompt message, which is convenient for the staff to deal with. With the help of RFID technology, the workload of personnel in traditional inventory management can be greatly reduced, and the inventory management of materials in and out of the warehouse can be achieved safely and efficiently.

The use of RFID coding method for container management can realize the automatic identification of materials across areas between the cargo area and the logistics area, so that the logistics of the goods can be tracked correctly and the workload of barcode scanning can be reduced. By associating the barcode of the goods in the container with the electronic label on the container, the container-level logistics management of the RFID long-distance electronic label can be realized.

The automatic sorting solution based on RFID technology, the RFID reading and writing device is installed on the key nodes of the conveying line, which can realize the tracking management of material information, and automatically record the operation process and operation time of the conveying goods, which can improve the conveying speed. , reduce sending errors. Compared with the traditional sorting system, the conveyor line of RFID technology has a lower error rate, can store more material information, is not affected by the placement direction of the goods, and has better scalability.

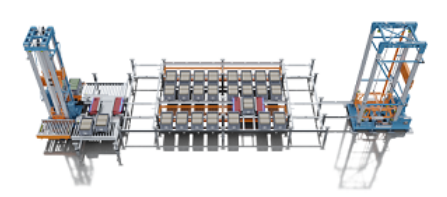

With the rapid development of RFID technology, warehousing and logistics management keeps pace with the times, andDigitizing, Intelligent development. Rapoo intelligent equipment adapts to market demand, applies RFID technology to scientifically deploy intelligent warehouses, and combines information technology to customize intelligent warehousing and logistics solutions for customers. Control and optimize the performance of each link of the warehousing operation process, provide customers with high-quality services in a fast, accurate and low-cost way, and make the warehousing and logistics operation more “smart”.

About Rapoo Intelligent Equipment

Shenzhen RapoorobotIntelligent Equipment Co., Ltd. (referred to as RRS Rapoo Intelligent Equipment) is committed to becoming a pioneer in professional services for intelligent warehousing and logistics. As early as 2012, the parent company, Rapoo Technology, began to explore the transformation of robot automated production and smart factories in the factory, and was selected as the first batch of intelligent manufacturing pilot demonstration units of the Ministry of Industry and Information Technology in 2015. The robot automation upgrade and transformation of the Rapoo factory itself has been widely recognized both inside and outside the industry, and has been reported by CCTV Economics for half an hour, KBS in Korea, and HBO in the United States. At present, it is mainly engaged in robot system integration, intelligent logistics equipment, automated three-dimensional warehouses and warehousing logistics equipment, tailor-made overall intelligent manufacturing solutions for customers, and jointly develop and design intelligent simulation systems and digital twin systems with several domestic universities. On the basis of equipment, it is deeply integrated into digitalization to help it build a digital intelligent factory, promote the transformation and upgrading process of intelligent manufacturing in China, and empower the manufacturing industry.

The Links: 3HAC024144-001 3BSE008514R1 DISPLAY

Pre: Regenerating wind power and photovolt... Next: Accused of developing spying tools to...