Development of China Industry Robot

China industrial robot started in the early 1970s of the last century. After more than 20 years of development, it has roughly experienced three stages: the budding period in the 1970s, the development period in the 1980s and the application period in the 1990s.

In 1970, my country also launched an artificial satellite. The application of industrial robots in the world has set off a climax, especially in Japan, where it has supplemented the increasingly scarce labor force. In this context, my country began to develop its own industrial robots in 1972.

After entering the 1980s, under the impact of the high-tech wave, with the continuous deepening of reform and opening up, the development and research of robot technology in my country has received the attention and support of the government. During the “Seventh Five-Year Plan” period, the state invested funds to tackle key problems in industrial robots and their parts, completed the development of a complete set of teaching and reproduction industrial robot technologies, and developed spraying, spot welding, arc welding and handling robots. In 1986, the national high-tech research and development plan (863 plan) was implemented. The theme of intelligent robot followed the frontier of the world’s robot technology. After several years of research, a large number of scientific research results were obtained, and a batch of special robots were successfully developed.

Since the early 1990s, my country’s national economy has entered into a period of two fundamental transformations, setting off a new round of economic system reform and technological progress. my country’s industrial robots have taken a big step forward in practice, and have developed some Welding, arc welding, assembly, painting, cutting, handling, packaging and palletizing and other industrial robots for various purposes, and implemented a number of robot application projects, forming a number of robot industrialization bases, which laid the foundation for the take-off of my country’s robot industry Base.

Although China’s industrial robot industry is making continuous progress, compared with its counterparts in the world, the gap is still obvious. From a physical point of view, it is even more incomparable. We have not yet mastered many core technologies of industrial robots, which is an important bottleneck affecting the development of my country’s robot industry.

With the gradual decline of the demographic dividend and the rising labor costs of enterprises, industrial robots are gradually entering the public’s field of vision. Analyst* of China Industry Insight Network believes that the continuous decline of the demographic dividend has brought major development opportunities to the robot industry; with the support of national policies, the industry is expected to usher in an explosive period.

The application field of industrial robots has also expanded. In 2010, in the German market, in addition to the automotive industry, the food industry significantly increased the use of robots. It can be seen that in the pharmaceutical and cosmetics industry and the plastics industry, the investment potential of robots is huge. Asia is expected to be the fastest growing region for the industrial robotics industry.

The “2014-2018 China Industrial Robot Industry Production and Sales Demand Forecast and Transformation and Upgrading Analysis Report” shows that in 2013, 36,560 industrial robots were sold in the Chinese market, accounting for one-fifth of the country’s sales, with a year-on-year increase of 60%, replacing Japan as the The world’s largest industrial robot market. It is estimated that the output value of ontology in 2014 will be about 9 billion yuan, and the market size of ontology plus integration will be about 27 billion yuan.

According to the “Outline of the Twelfth Five-Year Plan for National Economic and Social Development of the People’s Republic of China” issued in March 2011, China will accelerate the development of strategic new industries during the “Twelfth Five-Year Plan” period. *In the relevant decision, it was pointed out: “The development of strategic new industries has become a major strategy for major countries in the world to seize the commanding heights of a new round of economic and technological development”, including “equipment manufacturing industry”, “new material industry” and “new energy industry” And “Energy Saving and Environmental Protection Industry”. In the next ten years, the sales output value of my country’s equipment manufacturing industry will account for more than 30% of the sales output value of the entire equipment manufacturing industry. As an important part of the equipment manufacturing industry, the industrial robot industry will surely receive more policy support during this period to achieve further growth.

China will become the largest consumer of industrial robots by 2014. It is estimated that by 2015, China’s robot market demand will reach 35,000 units, accounting for 16.9% of the country’s total, becoming a large-scale robot market. Experts said that the compound growth rate of China’s industrial robot market will reach 30% in the next three years, and explosive growth is expected.

Although major enterprises are facing the pain of transformation and upgrading, many enterprises with strength and long-term vision have found a new way out in this pain. Shantui, as a large domestic manufacturer of construction machinery and a leading bulldozer company, should be at the forefront of its domestic counterparts in the application of automated welding equipment. It began to use welding robots and automatic welding machines in the mid-1990s. These measures have not only effectively improved the production efficiency of the enterprise, but also changed the traditional concept of employees.

At present, various standard components have been developed and produced abroad. As China is the main producer of industrial robots in the future, the process of standardization is the development trend.

China’s manufacturing industry is facing a transformation, and it is a huge challenge to undertake independent manufacturing and participate in international division of labor. Accelerating the research, development and production of industrial robot technology is the main way for China to seize this historical opportunity. Therefore, the development of my country’s industrial robot industry should be further implemented: Industrial robot technology is the main means and way for my country to transform from a manufacturing power to a manufacturing power. The government should have more policy and economic support for domestic industrial robots, refer to advanced experience, and strengthen Large-scale technology investment and transformation; second, in the national science and technology development plan, we should continue to give strong support to the research, development and application of intelligent robots, forming a new situation of synchronous coordination between products and automated manufacturing equipment; third, the quality of some domestic industrial robots Already comparable to foreign countries, enterprises should not blindly import industrial robots when purchasing industrial robots, but should comprehensively evaluate and base themselves on domestic production.

Intelligence and bionics are the high stages of industrial robots. With the continuous development of materials, control and other technologies, more and more laboratory products are commercialized and gradually applied to various occasions. With the development of the mobile Internet and the Internet of Things, there will be more and more precision industrial robots with multi-sensor and distributed control, gradually penetrating all aspects of the manufacturing industry, and transforming from manufacturing implementation type to service type.

The areas where industrial robots are first used on a large scale will appear in developed areas. With the progress of industrial transfer, the manufacturing industry in developed regions needs to be upgraded. Based on the reality of increasing labor costs, the application of industrial robots has become a good alternative. In the future, the large-scale application of industrial robots in my country will be concentrated in Guangdong, Jiangsu, Shanghai, Beijing and other places, and its industrial robot ownership will account for more than half of the country.

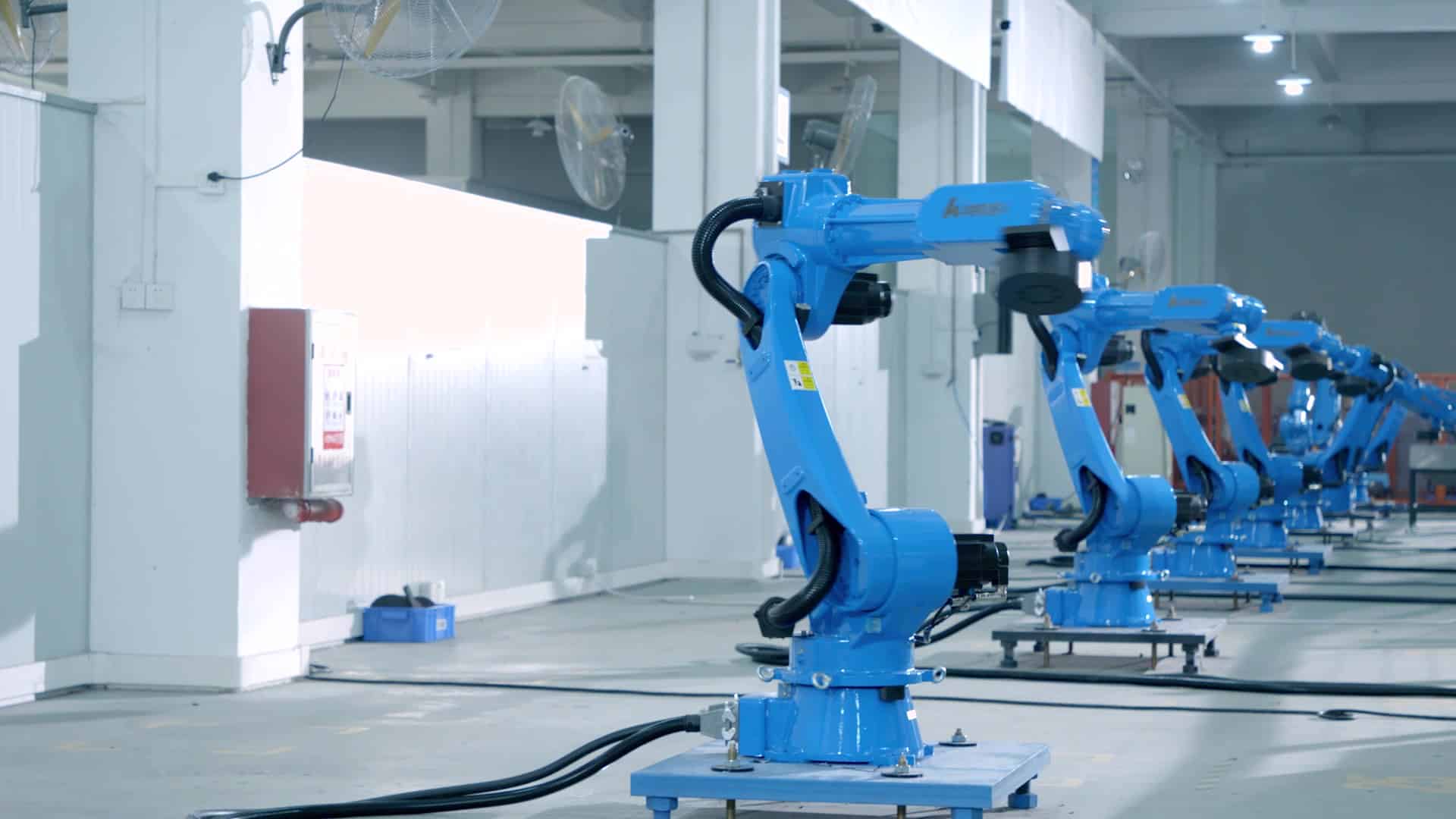

The growing industrial robot market and huge market potential have attracted the attention of world-renowned robot manufacturers. At present, the industrial robots imported by my country mainly come from Japan, but as companies with their own intellectual property rights such as “robots” continue to emerge, more and more industrial robots will be made in China.

Links: 1sap130300r0271 3bse008516r1

Pre: Composition of Industry Robot Next: The Development of Global Industry Robot